Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Sandwich Panel

PU Sandwich Panel

03Jul, 2024

PUF (polyurethane foam) roof panels are a high-performance building material, the core material of which is polyurethane rigid foam. Polyurethane is an organic polymer material made by polymerization of raw materials such as isocyanate and polyol, and has excellent physical and chemical properties. PUF roof panels usually consist of a multi-layer structure, including a waterproof layer on the surface, a polyurethane foam insulation layer in the middle, and possible bottom reinforcement materials. This structural design not only ensures the waterproof performance of the roof, but also provides excellent thermal insulation.

Application

PUF roof panels are widely used in various construction fields, including but not limited to large industrial plants, cold storage, garages, mobile homes, exhibition halls, gymnasiums, shopping centers, airports, power plants, villas, hospitals, and high-rise office buildings. Its excellent thermal insulation, waterproof and lightweight properties make PUF roof panels one of the most ideal roofing materials for steel structure plants, industrial and mining enterprises and civil buildings.

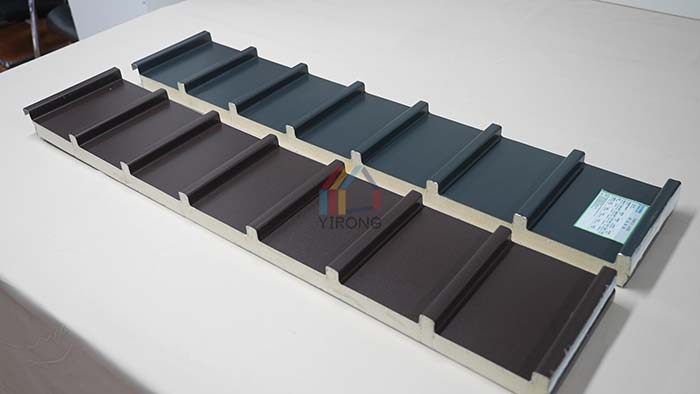

| Effective width | 950mm, 1000mm |

| Peak size with a width of 950mm | Peak height 15mm, peak spacing 119mm |

| Peak size with a width of 1000mm | Peak height 20mm, peak spacing 143mm |

| Steel plate thickness | 0.4mm To 0.8mm |

| Panel color | Metal ash, metal coffee or customize |

| Panel thickness | 30mm, 50mm, 75mm, 100mm |

| Core material | Polyurethane |

| Flame retardant grade | Grade B |

Features

Advantages

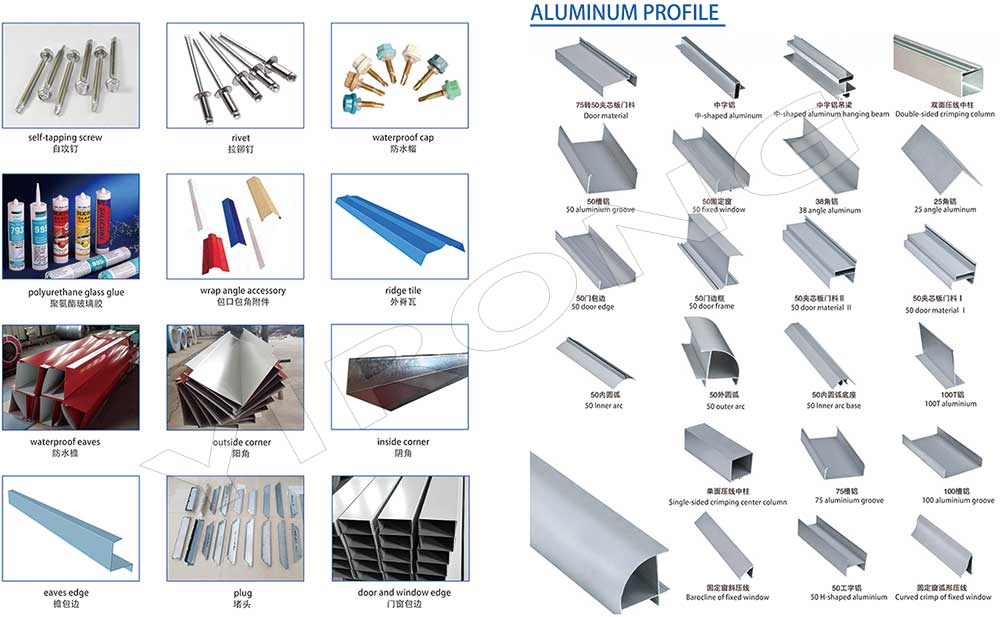

If you purchase metal sandwich panels from Yirong Company, we will also provide some accessory products, including self tapping nails, rivets, waterproof caps, polyurethane glass glue, mouth and corner accessories, outer ridge tiles, waterproof eaves, external and internal corners, eaves edging, plugs, door and window edging, purified aluminum profiles, etc.

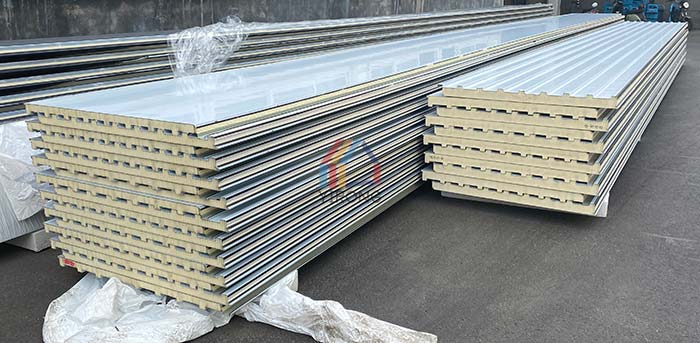

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers, who will prevent the goods to be damaged. And all the structure components, panels, bolts and sorts of accessories will be well packed with standard package and it is suitable for ocean transport.

1. Inspection: 50% inline inspection and 100% full final inspection, make sure all output w/o any mistake.

2. Packing: Per customer's requirements or per product sizes, full protection packing.

3. Shipping: Per customer's requirements or per container sizes.

4. Unloading: We package it as a whole and can be easily pulled out at once with a forklift, which is very convenient.