Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Sandwich Panel

Purification Board

29Jun, 2022

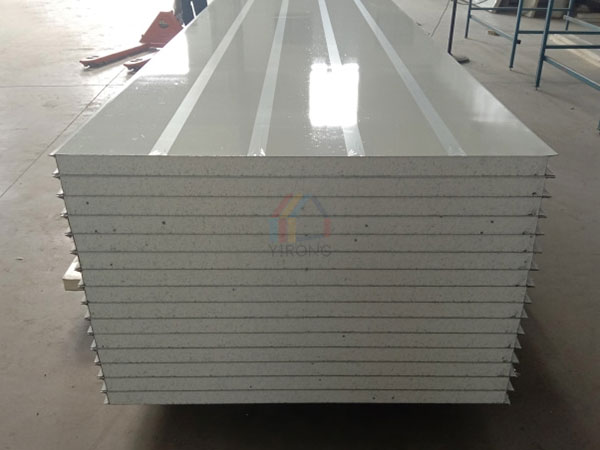

EPS purification board is actually a kind of mechanism type purification board. Its raw materials are generally color-coated board and stainless steel. In the period, it is a composite board made of EPS foam material. Because this EPS purification board has strong dust prevention and resistance to static electricity and bacteria, this EPS purification board generally pays more attention to precision and health standards in food processing, pharmaceutical processing, aerospace engineering, etc. It is used more by scientific research units.

The purification board itself has good thermal insulation performance. Under normal circumstances, the use of antibacterial clean board no longer requires the back liner insulation material, which can more effectively meet the energy saving standards.

Features of eps purification board:

Sound insulation, sound absorption and earthquake resistance, with the international advanced level of building interior decoration, interior partition decoration material requirements.

Durable weather resistance and acid and alkali resistance: The characteristics of fluorocarbon coatings make the board have good weather resistance and acid and alkali resistance. In the case of a large number of solvents and disinfectant cleaning in the medical clean room, the eps purification board can still be maintained. The color of the surface will not fade in the slightest.

The anti-static purification board uses special conductive pigments added to the color board coating, so that the surface of the color board has a resistance of 10-100. Static electricity can be released through this to prevent dust from attaching and easy to remove. At the same time, the eps sandwich panel has a resistance to Drugs, abrasion resistance, pollution resistance and other advantages. Special enamel antibacterial agent is used in the color plate coating of eps purification board, which has non-toxic and semi-antibacterial effect and far-infrared radiation effect.

In today's era of progress and rapid social development, there are higher requirements for purification projects in terms of environment, efficiency and function. Having a good preparation environment is obvious for the purification project or for the improvement of efficiency, but if you want to have a good purification project, a qualified purification workshop, and good materials are very important, EPS purification board is obviously a good choice.

Yirong is a manufacturer of sandwich panels. Our EPS purification panels use color-coated panels as the middle layer, and special materials are placed in them to achieve excellent resistance to static electricity. However, it has good resistance to dust deposition. It is more convenient and easy to maintain and clean. It can be said that the advantages of EPS purification boards are very large for purification projects.

EPS purification board also has certain effects such as wear resistance, stain resistance, antibacterial and so on. I believe that if you choose EPS purification board, you will have a good effect and experience.

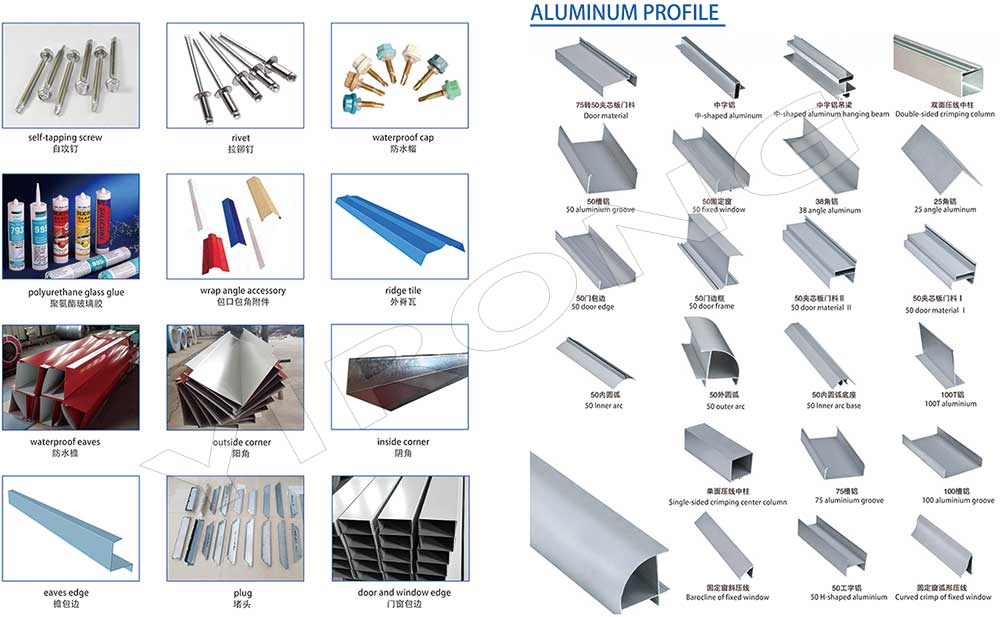

If you purchase metal sandwich panels from Yirong Company, we will also provide some accessory products, including self tapping nails, rivets, waterproof caps, polyurethane glass glue, mouth and corner accessories, outer ridge tiles, waterproof eaves, external and internal corners, eaves edging, plugs, door and window edging, purified aluminum profiles, etc.

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers, who will prevent the goods to be damaged. And all the structure components, panels, bolts and sorts of accessories will be well packed with standard package and it is suitable for ocean transport.

1. Inspection: 50% inline inspection and 100% full final inspection, make sure all output w/o any mistake.

2. Packing: Per customer's requirements or per product sizes, full protection packing.

3. Shipping: Per customer's requirements or per container sizes.

4. Unloading: We package it as a whole and can be easily pulled out at once with a forklift, which is very convenient.