Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Sandwich Panel

Color Steel Sheet

30Jun, 2022

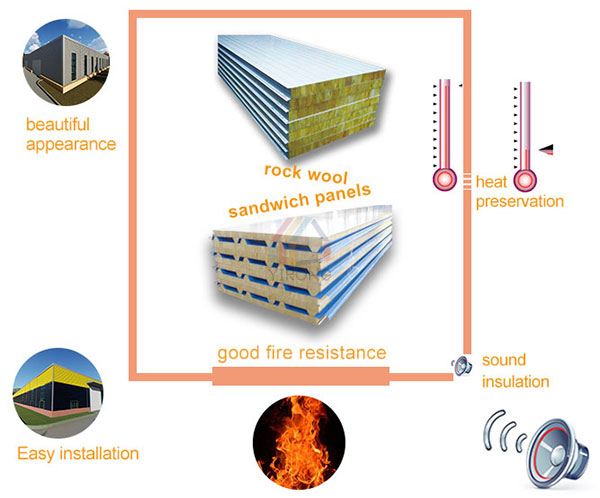

As a new type of building board, color steel rockwool panel is widely used in mobile board room, paint baking room and electronic clean room. As a new type of sandwich panel, color steel rockwool panel has the characteristics of good fire resistance, heat preservation and heat insulation performance.

Characteristics of color steel rock wool sandwich panel

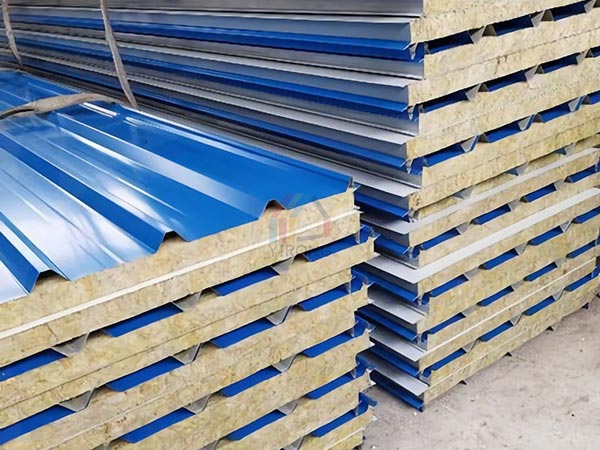

Color steel rock wool sandwich panel is made of 0.7mm color coated steel decorative panel as the surface layer and rock wool panel as the core body, which is formed by composite pressing. Color steel rock wool panel has light weight, thermal conductivity, good seismic performance and sealing performance, sufficient mechanical properties, and can be widely used in non-load-bearing walls. And the construction is completely on-site assembly, only small electric and manual tools are used. Can achieve. The surface of the assembled sandwich panel does not need exterior decoration and waterproof measures.

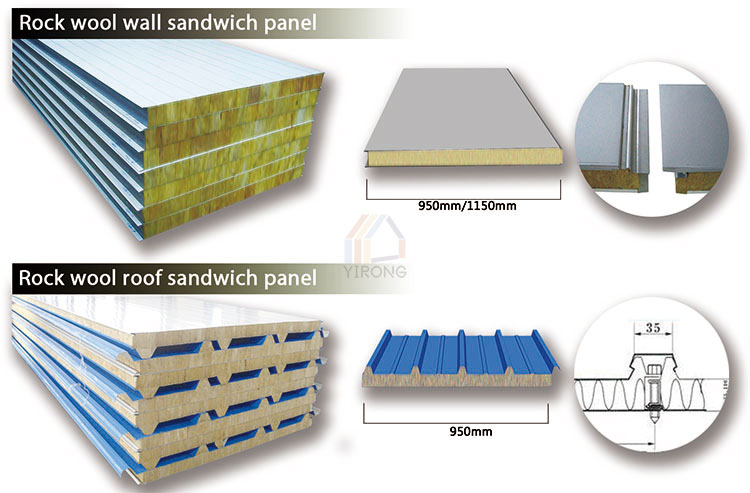

| Effective width | 950mm/1150mm |

| Color steel thickness | 0.2mm-0.8mm |

| Rock wool thickness | 50mm/75mm/100mm/150mm |

| Sheet material | Cold rolled substrate, stainless steel sheet |

| Sheet color | Blue/Red/White/Customize |

| Features | Fire retardant, thermal insulation |

| Application | Cold storage, clean room, warehouse, factory workshop, container house |

Classification of color steel rock wool sandwich panels

Color steel rock wool sandwich panels can be divided into wall panels, roof panels and fire doors according to different parts of use.

Wall panels. Mainly used as walls of building structures. It can be divided into ordinary siding, generally the maximum length is 2400mm. There are also double female siding, the maximum length is 3500mm under normal circumstances.

Roof panels. Mainly used as a suspended ceiling for building structures. The ceiling color steel rock wool sandwich panel can also be divided into the shelving ceiling color steel rock wool sandwich panel and the suspended ceiling color steel rock wool sandwich panel.

Fire doors. Mainly used as fire doors in building structures. Among them, the door frame is mostly made of 1.5mm cold-rolled steel plate, and the door leaf is mostly made of 1.2mm cold-rolled steel plate.

Features:

1. Rock wool is an inorganic thermal insulation material. It is made of iron ore slag as the main raw material. It is melted and cooled by high-pressure steam. The advantage of chemical stability. It also has excellent sound insulation properties.

2. Rock wool sandwich panels are widely used in various fireproof and soundproof places in addition to the general movable structures that play the role of thermal insulation.

Product performance:

1. Thermal insulation performance. Good thermal insulation performance is the basic characteristic of rock wool, and their thermal conductivity is under normal temperature conditions (about 25 ℃).

2. Combustion performance. The combustion performance of rock wool depends on the amount of flammable binder in it. Rock wool itself is an inorganic silicate fiber and is not flammable. In the process of processing into products, organic binders or additives are sometimes added, which will have a certain impact on the combustion performance of the products.

3. Sound insulation performance. Rock wool has excellent sound insulation and sound absorption properties, and its sound absorption mechanism is that this product has a porous structure. When the sound wave passes through, friction is generated due to the action of flow resistance, so that part of the sound energy is absorbed by the fiber, which hinders the transmission of the sound wave.

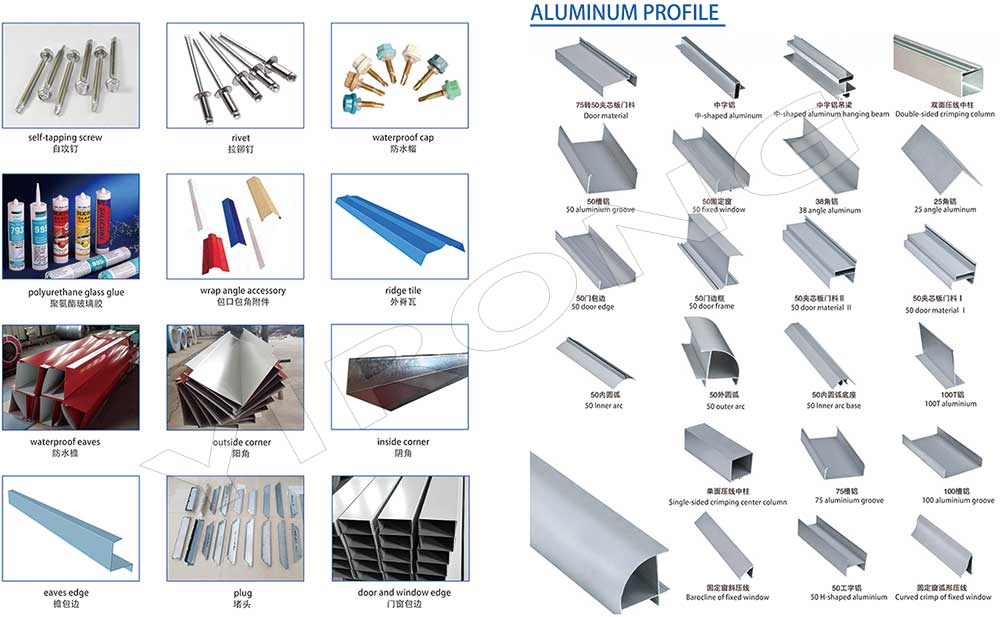

If you purchase metal sandwich panels from Yirong Company, we will also provide some accessory products, including self tapping nails, rivets, waterproof caps, polyurethane glass glue, mouth and corner accessories, outer ridge tiles, waterproof eaves, external and internal corners, eaves edging, plugs, door and window edging, purified aluminum profiles, etc.

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers, who will prevent the goods to be damaged. And all the structure components, panels, bolts and sorts of accessories will be well packed with standard package and it is suitable for ocean transport.

1. Inspection: 50% inline inspection and 100% full final inspection, make sure all output w/o any mistake.

2. Packing: Per customer's requirements or per product sizes, full protection packing.

3. Shipping: Per customer's requirements or per container sizes.

4. Unloading: We package it as a whole and can be easily pulled out at once with a forklift, which is very convenient.