Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Sandwich Panel

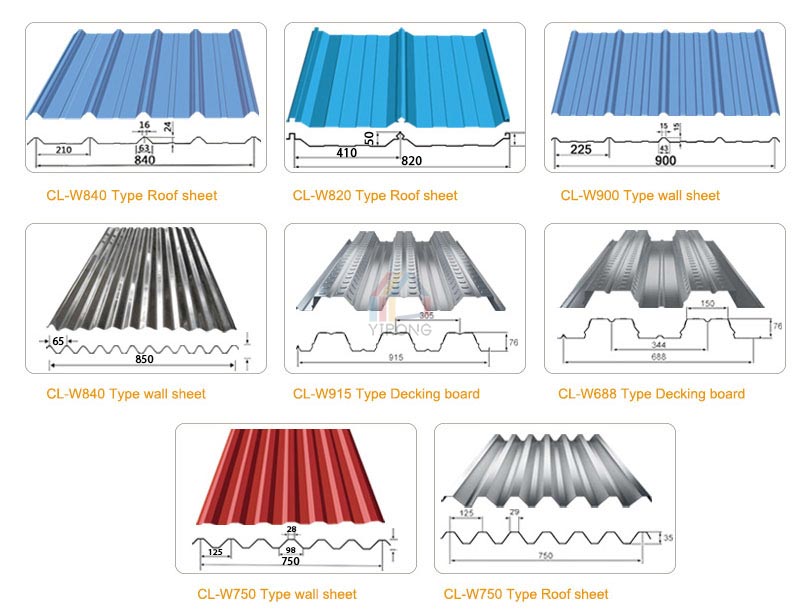

Color Steel Sheet

09Jun, 2022

Color steel sandwich panel is a special kind of normally used construction material in steel structure building industry with color coated steel sheets at the top and bottom for surface material with middle part insulation materials, like self extinguishing eps/polystyrene, rock wool/mineral wool, glass wool/fiberglass wool, pu/polyurethane, etc which is suitable for different building usage.

Rock wool as one kind of core insulation material, ultra light building board with thermosetting rubber molding machine in continuous heating and pressurizing and compounding. It has the advantages of light weight (for concrete roof weight 1/20 - 1/30), insulation (the thermal conductivity coefficient is 0.034w/mk), fast construction speed (no wet, not the two time decoration, the construction period can be shortened by about 40 percent), bright colour (no any more surface decoration, colour galvanized steel coating retention period is 15-20 years) characteristics.

In a set of bearing, thermal insulation, waterproof, decoration in one of the new type of envelope materials.

The color steel sheet is light weight compared to concrete structure building material so that it’s much more easy for the installation worker to assemble with less time. The light weight sandwich panel features, splicing installtion and free cutting to many customized shapes, the installation is simpler and can greatly improve efficiency to save construction time.

Color steel sandwich panel surface materials and insulation materials for non combustible materials can completely meet the fire safety requirements.

Various research shows and abroad for more than 40 years that is widely used by special coating color steel shelf life in 15-20 years, every 10 years after spraying coatings, sheet lofe up to 30-35 years.

We could customize the panel outside appearance colour based on Germany RAL color card, clear clines of pressure plate up to dozens of colors, can be matched with any style of architecture, to achieve satisfactory results.

Core materials and different plate composite sandwich plate is not same, which could be applied to different buildings, including a pourality of building industrial plants, public buildings, purification workshop engineering, cold room, houses, etc. Sandwich panel due to its advantage it is widly used in different kinds of building, in addition to the field, people also give full play to its characteristics, it is applied to the broaded field, such as ship partition, animal breeding building, highway sound insulation wall, and so on. With the advancement of science and technology and people’s work and life needs upgrading, so as to better meet the needs of the people, to create a broader space in a new layer of building materials industry.

When you have a house or industry building needed to cover please you could send me the size(long x wide x high) and we could calculate roof and wall sandwich panel use quantity with our professional knowledge and experience.

We are always here welcome for your sandwich panel inquiry.

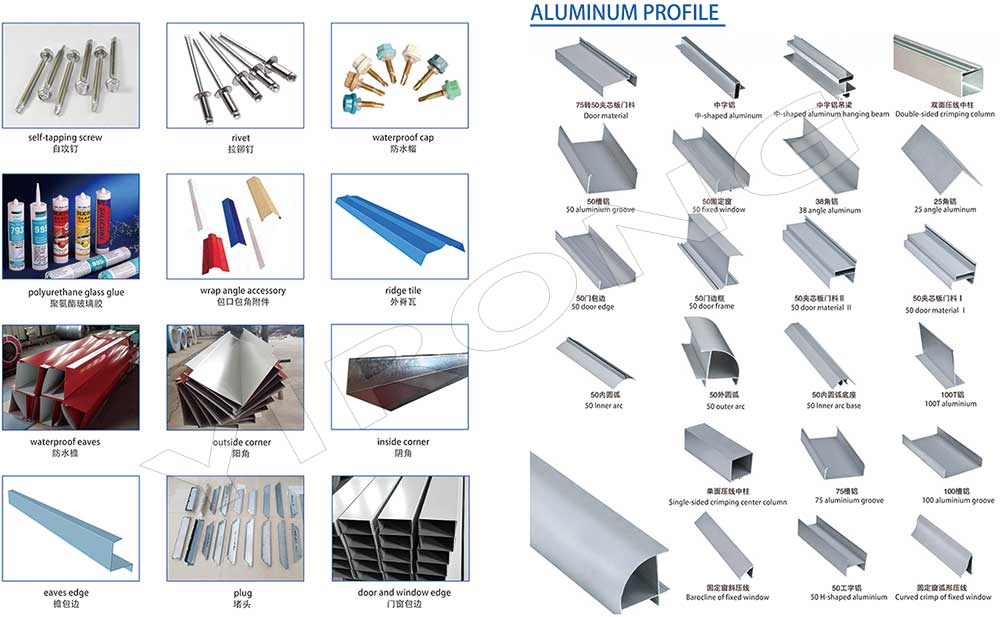

If you purchase metal sandwich panels from Yirong Company, we will also provide some accessory products, including self tapping nails, rivets, waterproof caps, polyurethane glass glue, mouth and corner accessories, outer ridge tiles, waterproof eaves, external and internal corners, eaves edging, plugs, door and window edging, purified aluminum profiles, etc.

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers, who will prevent the goods to be damaged. And all the structure components, panels, bolts and sorts of accessories will be well packed with standard package and it is suitable for ocean transport.

1. Inspection: 50% inline inspection and 100% full final inspection, make sure all output w/o any mistake.

2. Packing: Per customer's requirements or per product sizes, full protection packing.

3. Shipping: Per customer's requirements or per container sizes.

4. Unloading: We package it as a whole and can be easily pulled out at once with a forklift, which is very convenient.