Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Sandwich Panel

PU Sandwich Panel

28Jun, 2022

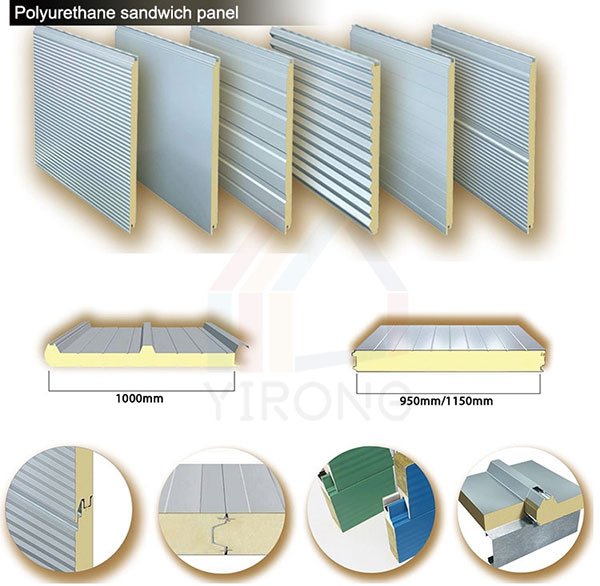

Polyurethane roof panel is also called PU sandwich roof panel. The composite board with polyurethane as the core material is composed of upper and lower color steel plates and intermediate foamed polyurethane. It adopts six-component online automatic operation mixing and pouring technology, which can complete the mixing process of social batching centers or factories online at one time, and can be adjusted according to the temperature. It can be adjusted freely online to produce distinctive high-strength, energy-saving building panels.

| Effective coverage width | 1000mm/1m |

| Panel effect | Outer panel high wave crest |

| Color steel plate thickness | 0.4mm To 0.8mm |

| Color of color steel plate | Customer customize |

| PU core thickness | 50mm/75mm/80mm/100mm |

| Core material | Polyurethane/PU |

| Flame retardant grade | Grade B |

| Application | industrial workshop, cold storage, garages, mobile houses, warehouse |

Pu sandwich panels are generally used for the roof outer layer of buildings, which have good thermal insulation, heat insulation and sound insulation effects. And polyurethane does not support combustion, the combined effect of the upper and lower panels and polyurethane has high strength and rigidity, the lower panel is smooth and flat, the lines are clear, and the indoor aesthetics and flatness are increased. The pu sandwich roof panel is easy to install, has a short construction period and is beautiful. It is a new type of building material.

Polyurethane sandwich panels are lightweight, beautiful, and can be directly processed. It provides a new type of raw material for the construction industry, shipbuilding industry, vehicle manufacturing industry, furniture industry, electrical industry, etc., and has achieved good effects such as replacing wood with steel, saving energy, and preventing pollution.

In the production process of pu composite board, an assembly line is used, and the degree of automation reaches more than 90%. While saving labor, it can more effectively reduce human control and improve product quality.

As a building energy-saving thermal insulation material, polyurethane composite panels have been widely used in developed countries such as Europe, the United States, and Japan, with a penetration rate of 80%. As an excellent energy-saving thermal insulation material, pu sandwich panel can provide a solution to the global energy consumption crisis with its thermal insulation, fire protection and thermal insulation properties.

PU sandwich roof panels are widely used in large industrial workshops, cold storage, garages, mobile houses, exhibition halls, exhibition halls, gymnasiums, shopping centers, airports, power plants, villas, hospitals, strata and high-rise office buildings, etc. The main application of thermal insulation performance For roofs and walls of industrial and civil buildings.

Advantages of pu roof panels

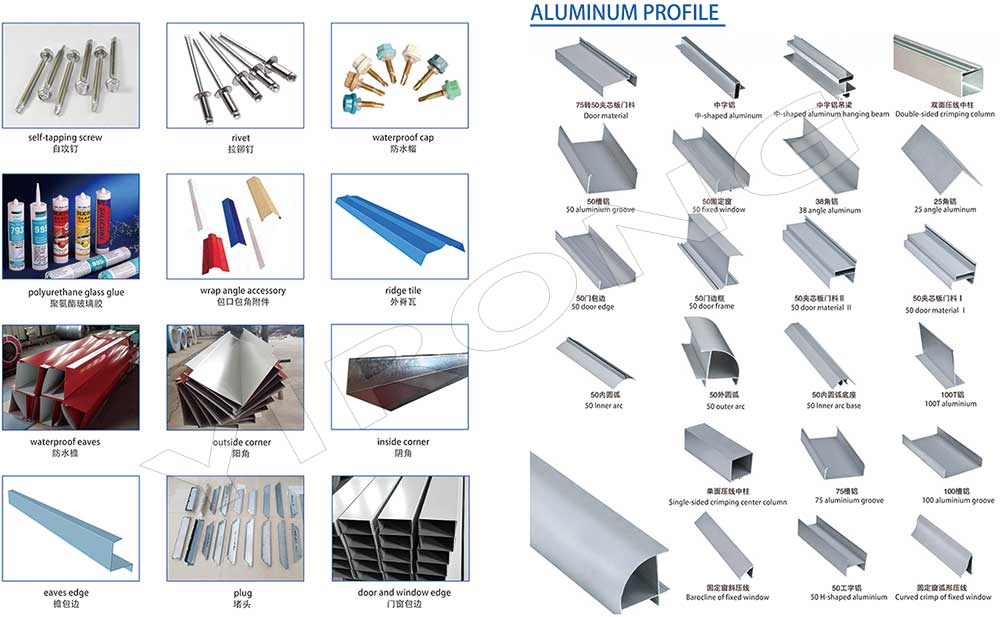

If you purchase metal sandwich panels from Yirong Company, we will also provide some accessory products, including self tapping nails, rivets, waterproof caps, polyurethane glass glue, mouth and corner accessories, outer ridge tiles, waterproof eaves, external and internal corners, eaves edging, plugs, door and window edging, purified aluminum profiles, etc.

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers, who will prevent the goods to be damaged. And all the structure components, panels, bolts and sorts of accessories will be well packed with standard package and it is suitable for ocean transport.

1. Inspection: 50% inline inspection and 100% full final inspection, make sure all output w/o any mistake.

2. Packing: Per customer's requirements or per product sizes, full protection packing.

3. Shipping: Per customer's requirements or per container sizes.

4. Unloading: We package it as a whole and can be easily pulled out at once with a forklift, which is very convenient.