Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Sandwich Panel

PU Sandwich Panel

16Jun, 2022

What is polyurethane sandwich panel?

Polyurethane sandwich panel is also known as polyurethane composite panel, polyurethane energy-saving panel and PU panle. The correct statement is that polyurethane insulation sandwich panels are used for construction.

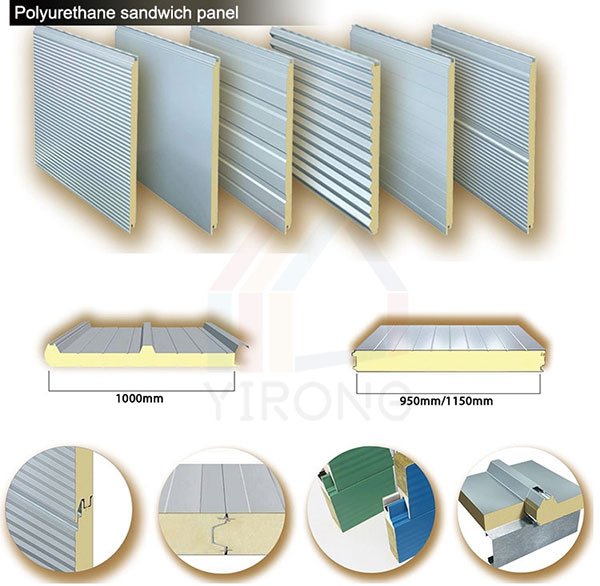

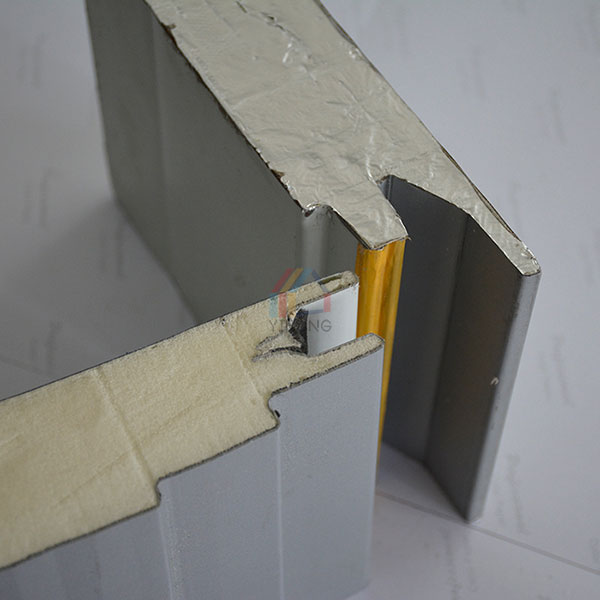

Polyurethane sandwich panels are bimetallic, single metal and non-metal composite panels with polyurethane rigid foam as insulation layer. It is usually used for the wall and roof enclosure system of industrial plants, logistics storage and integrated houses.

Characteristics of polyurethane sandwich panel:

(1) Low thermal conductivity. PU composite panel has small thermal conductivity and good thermal insulation performance. It is the best thermal insulation material.

(2) Beautiful plate shape and convenient installation.

(3) Polyurethane sandwich board has good fire resistance.

(4) Polyurethane composite panel is non-toxic and tasteless.

(5) Wide temperature range.

(6) Waterproof and moisture proof.

Polyurethane sandwich panel has beautiful appearance and good overall effect. It integrates load-bearing, heat preservation, fire prevention and waterproof. Moreover, it does not need secondary decoration. It has the advantages of fast and convenient installation, short construction period, good comprehensive benefits and good cost performance. PU panel is a kind of high-efficiency and energy-saving building envelope material with wide use and great potential, and it is also a new type of energy-saving board.

Polyurethane composite sandwich panels are widely used in energy-saving industrial plants, civil buildings, residential buildings, etc., with the advantages of beautiful atmosphere, energy conservation and thermal insulation, long service life, etc.

| Effective coverage width | 950mm-1150mm |

| Panel effect | Upper plate high wave crest/Under the flat plate |

| Service life | 25 years |

| Sheet /PU thickness | 0.2mm-0.8mm, 50mm/75mm/100mm/150mm |

| Sheet color | Customer customize |

| Core material | Polyurethane/PU |

| Application | Cold storage, clean room, silencing system, enclosure system |

Introduction of polyurethane

Polyurethane (PUR) refers to a large class of polymers with more urethane groups in the main chain. It is a kind of polymer material between plastic and rubber. It has large elongation, wide hardness range, wide formula adjustment range, and excellent wear resistance and mechanical properties.

Polyurethane sandwich panel is produced by casting polyurethane elastomer process. Polyurethane is a kind of polymer that contains urethane type repeating structural units in the macromolecular chain. It is called polyamino acid ester in its full name and polyurethane in its full name in the UK, referred to as PU or PUR for short. Pu is the product of polyisocyanate and polyether or polyester polyol in a certain proportion.

Performance of PU elastomer: the performance of PU elastomer is slightly different from that of PU elastomer synthesized by plastic polyol. Polyester Pu has high mechanical properties, good oil resistance, but poor water resistance. The low temperature resistance and hydrolysis resistance of polyether Pu are better than those of polyester Pu, but the oil resistance and mechanical properties are slightly worse.

Mechanical properties of Pu: the hardness of PU elastomer varies widely from shore A10 to D80, with a breaking elongation of 800%. The shore hardness of natural rubber is only A70, and the elongation at break is 550%. PU elastomer has higher tear strength, 2-5 times greater than natural rubber. PU elastomer has high resilience and good shock absorption effect. PU elastomer has good wear resistance, which is 3-10 times that of natural rubber.

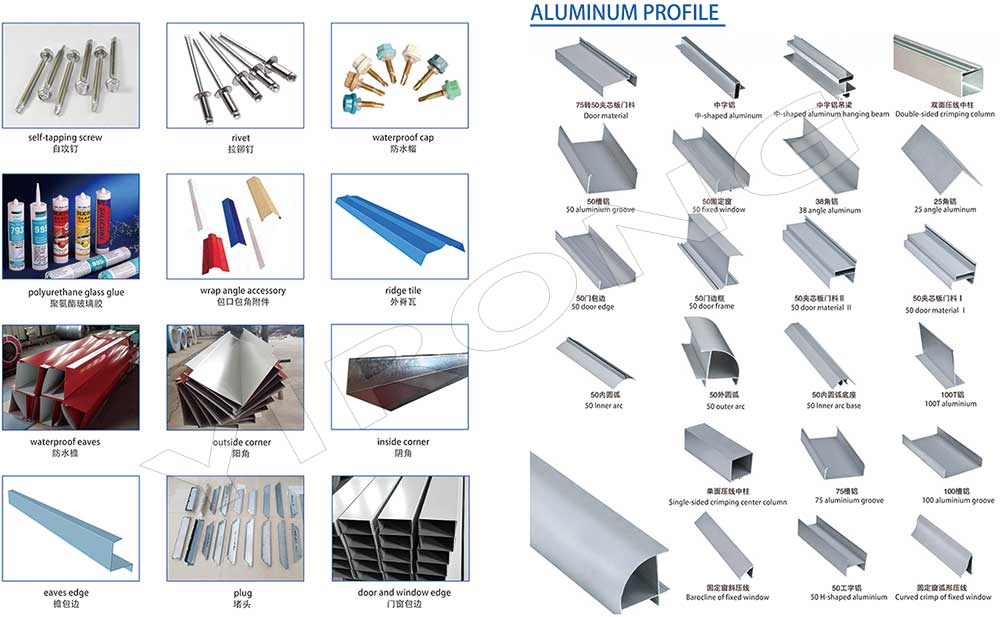

If you purchase metal sandwich panels from Yirong Company, we will also provide some accessory products, including self tapping nails, rivets, waterproof caps, polyurethane glass glue, mouth and corner accessories, outer ridge tiles, waterproof eaves, external and internal corners, eaves edging, plugs, door and window edging, purified aluminum profiles, etc.

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers, who will prevent the goods to be damaged. And all the structure components, panels, bolts and sorts of accessories will be well packed with standard package and it is suitable for ocean transport.

1. Inspection: 50% inline inspection and 100% full final inspection, make sure all output w/o any mistake.

2. Packing: Per customer's requirements or per product sizes, full protection packing.

3. Shipping: Per customer's requirements or per container sizes.

4. Unloading: We package it as a whole and can be easily pulled out at once with a forklift, which is very convenient.