Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Sandwich Panel

PU Sandwich Panel

09Jun, 2022

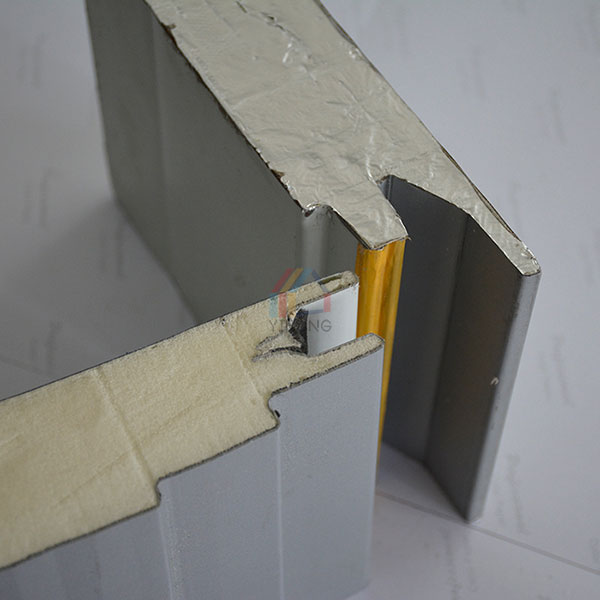

Polyurethane sandwich panel is a product used to cover the walls and roofs of buildings. Each panel contains a core of thermal insulation material and is covered with metal plates on both sides. Sandwich panels are not structural materials, but curtain materials. The structural force is carried by the steel frame or other load-bearing frame attached to the sandwich plate.

Polyurethane sandwich wall panel is easy to install. From practical experience, it takes about 8 hours for skilled construction personnel to install 600 square meters of sandwich panels.

The steps for installing polyurethane wall panel are as follows:

1. Transportation of construction materials to the site: transportation includes sandwich panels, subframe components (cold-formed profiles), accessories (including waterproof boards, fasteners, gaskets, seals, etc.). Yirong can provide all components required to complete the installation process.

2. Materials transported by the carrier shall be unloaded with construction handling equipment.

3. Assemble the subframe and install the beam, column and purlin.

4. Remove the protective film on the Pu sandwich panel.

5. Fix the Pu panel to the subframe structural member with appropriate fasteners.

6. The joints between sandwich panels shall be sealed and waterproof boards shall be installed.

Features of polyurethane sandwich wall panel:

1. Light weight and earthquake resistance: compared with clay solid bricks, light wall panels are more than ten times lighter, and more than 100kg lighter than hollow blocks. Solve the problems of girder, column and deep foundation. Plate column connections have good seismic performance. It is not only applicable to low-rise buildings, but also to high-rise buildings, soft geology, beach and beach buildings.

2. Good thermal insulation performance: many vacuum bubbles are formed inside the composite wallboard during the production process. These bubbles form a static air layer in the material, so that the thermal conductivity of the plate is only 0.12w/mk and the thermal resistance is 2.00. It can greatly reduce the cost of electricity and coal, such as heating and cooling, and is a good choice for energy conservation.

3. Good sound insulation and waterproof performance: the plate has a closed microporous structure inside, which effectively blocks the sound transmission and sound absorption. The sound insulation is ≥ 40dB, and the waterproof, moisture-proof and freeze-thaw resistance all meet the standards.

4. Increase the use area: the Pu panel wall is thin, which can increase the use area by more than 8 ~ 10%.

5. Good installation and processing performance: Polyurethane wall panel can be sawn, nailed, drilled, cut at will, and make architectural patterns at will.

6. Fast construction: dry operation, simple and convenient installation, more than 6 times faster than the block wall, which can greatly shorten the construction period.

7. Good surface decoration performance: the polyurethane sandwich wallboard has good surface flatness, and can be directly pasted with wallpaper, wall tiles and sprayed after caulking.

8. Low comprehensive cost: due to the reduction of beam column and foundation load, the construction is fast and the cycle is short, which reduces the project cost by 20% compared with clay brick and hollow block.

9. Civilized construction: dry method construction, site material specification, less construction waste and high construction civilization.

10. Environmental protection, energy conservation and waste utilization: Polyurethane wall panels materials do not contain toxic and harmful substances, and waste utilization and energy conservation are green products promoted and developed by the state.

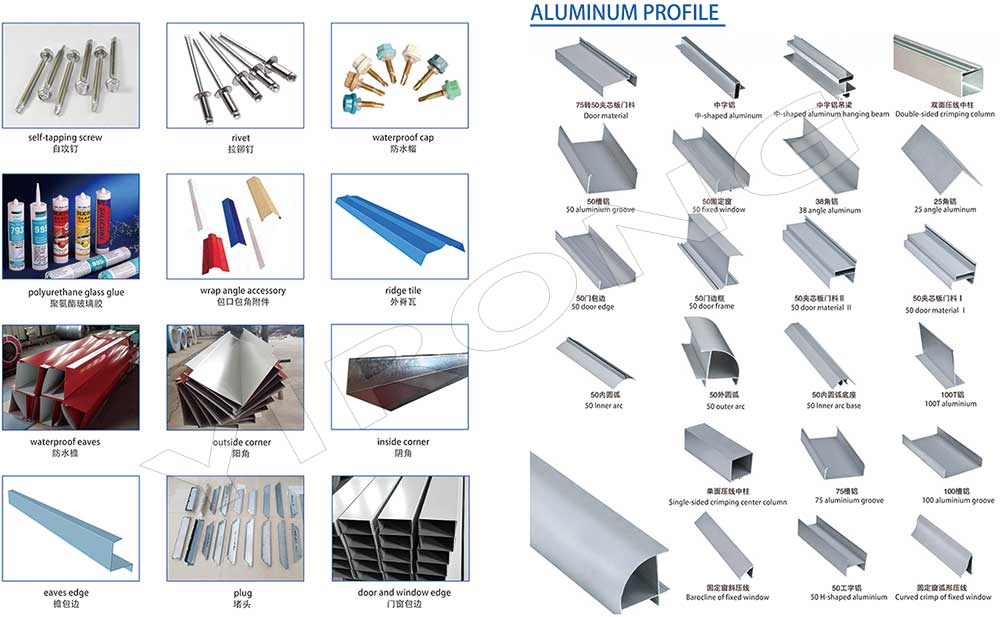

If you purchase metal sandwich panels from Yirong Company, we will also provide some accessory products, including self tapping nails, rivets, waterproof caps, polyurethane glass glue, mouth and corner accessories, outer ridge tiles, waterproof eaves, external and internal corners, eaves edging, plugs, door and window edging, purified aluminum profiles, etc.

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers, who will prevent the goods to be damaged. And all the structure components, panels, bolts and sorts of accessories will be well packed with standard package and it is suitable for ocean transport.

1. Inspection: 50% inline inspection and 100% full final inspection, make sure all output w/o any mistake.

2. Packing: Per customer's requirements or per product sizes, full protection packing.

3. Shipping: Per customer's requirements or per container sizes.

4. Unloading: We package it as a whole and can be easily pulled out at once with a forklift, which is very convenient.