Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

With the acceleration of global urbanization, commercial buildings are facing two core challenges: fire safety upgrades and pressure to achieve carbon neutrality targets. According to data from the International Energy Agency (IEA), the construction industry contributes 38% of global carbon emissions, and the choice of fire-resistant materials directly affects building safety and energy efficiency. In this context, PU sealing edge rock wool sandwich panel has become the preferred material for commercial building worldwide due to their A-level fire resistance, excellent insulation, and low-carbon properties.

1.1. Driven by the demand for upgrading international fire safety standards

EU: Starting from 2023, all newly constructed high-rise commercial building must comply with the Building Energy Efficiency Directive (EPBD) and be required to use Class A1 non combustible materials (such as rock wool sandwich panels).

USA: NFPA 13 new regulations require that the thermal conductivity of fire insulation materials in the atrium area of commercial complexes be ≤ 0.04 W/(m · K), and PU sealing edge rock wool sandwich panel has become the mainstream choice.

Middle East: Saudi Arabia's NEOM Future City and other mega projects prioritize the use of integrated fire-resistant and photovoltaic building materials to promote energy conservation and safety compliance.

1.2. Carbon neutrality targets drive material innovation

Traditional polystyrene sandwich panels (EPS) have 60% higher carbon emissions than rock wool due to the presence of fossil fuel components. The PU edge sealed rock wool sandwich panel is made of natural basalt as raw material, which reduces carbon emissions by 45% during the production process and has the following advantages:

Fire resistance performance: The rock wool core material has a fire resistance limit of 4 hours (A1 level), far exceeding the B1 level (flame retardant) of EPS sandwich panels.

Thermal insulation and energy saving: With a thermal conductivity coefficient as low as 0.028 W/(m · K), it helps commercial building meet LEED/BREEAM certification.

Structural strength: PU edge sealing technology increases the compressive strength of the board by 30% and the wind pressure resistance performance reaches 5.5 kPa.

2.1. Super high-rise commercial complex

Shanghai center Building: PU sealing edge rock wool sandwich panel is used as the thermal insulation layer of the curtain wall, the fire rating reaches A1, and the energy consumption of air conditioning is reduced by 25%.

Dubai Burj Khalifa: Use this board in the refuge layer to achieve 72 hour fire isolation and comply with FS1 standards in the Middle East.

2.2. Industrial logistics park

Amazon Europe Logistics Center: Using fire-resistant sandwich panels to build warehouse roofs, balancing fire resistance with 48% annual solar reflectivity (high reflectivity coating technology).

Tesla Berlin Gigafactory: Integrating photovoltaic panels with rock wool sandwich panels to create a benchmark for a "zero carbon factory".

2.3. Renovation commercial projects

Old renovation of Canary Wharf in London: laying PU edge sealed rock wool board on the existing steel structure, shortening the construction period by 40% and reducing carbon emissions by 35%.

3.1. Core parameters and certification standards

Fire certification: UL 723 (American standard), BS 8414 (British standard), EN 13501-1 (European standard) are all indispensable.

Physical properties: Tensile strength ≥ 1.5 MPa, water absorption rate ≤ 3%, edge anti delamination PU edge sealing process is an additional item.

Environmental certification: EPD (Environmental Product Declaration), GREENGUARD Gold (Low VOC Emissions).

3.2. Distribution of mainstream suppliers and procurement strategies

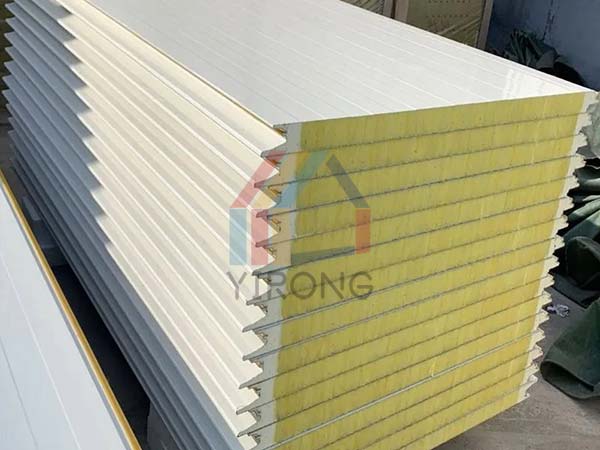

China: accounting for 65% of global production capacity, represented by companies such as Canglong Group, Yirong Integrated Housing, and Sinoma Technology (providing UL certified customized services).

Europe: BASF from Germany and Xylem from Sweden focus on high fire rated boards, suitable for the high-end market in Western Europe.

Southeast Asia: Sungei Gaharu from Malaysia seizes the ASEAN market with its FOB price advantage.

3.3. Cross border procurement avoidance guide

Beware of low price traps: Boards with rock wool content below 80% may falsely label their fire rating and require inspection of third-party testing reports (such as SGS).

Logistics and Quality Assurance: Priority should be given to CIF terms (including marine insurance), and the factory is required to provide a 10-year warranty and free replacement terms for cracking and deformation.

Under the dual wave of global building safety and low-carbon transformation, PU sealing edge rock wool sandwich panels are upgrading from functional materials to strategic building materials. For builders, choosing suppliers that meet international certifications and support customized services (such as top Chinese manufacturers) can not only meet the demands of high-end markets in Europe and America, but also reduce the full lifecycle cost through energy-saving design. With the implementation of the EU Carbon Tariffs (CBAM), the early layout of a fire resistant and low-carbon building materials supply chain will become the core barrier for companies to win global bidding.