Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Cleanroom wall panels are not just physical partitions, but also key components for maintaining controlled environmental levels, pressure differentials, and operational energy consumption. Faced with increasingly segmented clean room needs in industries such as electronics, pharmaceuticals, and food, as well as varying fire and moisture control standards across different regions, how can you quickly make the right selection? This article explores four dimensions: materials, surface treatment, standard certification, and industry compatibility, helping you make the right choice in one step.

The core of a clean room lies in controlling particles and microorganisms. If the wall panels have rough surfaces, leaky seams, or moisture-absorbing substrates, they will not only easily accumulate dust but may also lead to inaccurate air exchange rates and soaring energy consumption. Correct selection is the first step in ensuring ISO 14644 standards, GMP compliance, and long-term operational benefits.

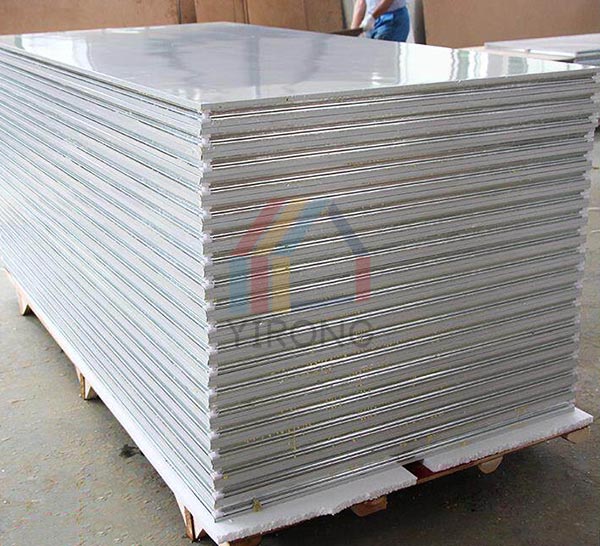

Metal-faced sandwich panels: Double-sided color-coated steel/stainless steel, core material options include rock wool (fire-resistant), aluminum honeycomb, and magnesium oxide.

Inorganic Boards: Calcium silicate board, high-pressure resin board, suitable for high temperature, high humidity, or highly corrosive environments.

Transparent Partitions: Double-layered tempered insulating glass with embedded blinds, balancing light transmission and observation.

Coatings: Polyester (PE), Silicon-modified Polyester (SMP), Fluorocarbon (PVDF). PVDF offers superior weather resistance and chemical resistance, suitable for electronics factories.

Antibacterial Film: PVC/PP antibacterial film, resistant to hydrogen peroxide sterilization, the preferred choice for biopharmaceuticals.

Antistatic: Surface resistance 10⁶–10⁹ Ω, preventing electrostatic adsorption of particles.

Tee and Joint Connections: Equipped with continuous EPDM sealing strips; leakage rate must meet ISO 14644-3 Class B.

Rounded Transitions: Wall bases and corners use aluminum alloy profiles with R≥50 mm, eliminating dead corners and facilitating cleaning.

Modular Inspection Ports: Quick assembly and disassembly for easy equipment maintenance.

The selection of cleanroom wall panels must simultaneously meet the following international standards; none can be omitted:

ISO 14644-4: Enclosure materials must not generate dust, adsorb, or breed microorganisms.

EU GMP / China GMP: Smooth, non-porous surface, resistant to disinfectants, and with smooth, seamless seams.

NEBB / Cleanroom Airtightness Test: Actual pressure differential attenuation or smoke detection data after construction.

It is recommended to clearly specify the following in the procurement technical specifications: Fire resistance rating EN 13501-1 B-s1,d0, formaldehyde emission ≤0.05 mg/m³, and mildew resistance rating 0.

Recommended: Hot-dip galvanized steel sheet + conductive PVDF coating.

Key point: Joints must be argon arc welded and leveled to prevent electrostatic discharge (ESD) damage to wafers.

Recommended: 304/316 stainless steel sandwich panels or magnesium oxide rock wool panels.

Key points: Continuous welding of the arc joint to the ground, resistance to VHP sterilization.

Recommended: High-density PVC panels or PE-coated steel panels.

Key points: Balancing corrosion resistance with initial investment.

Recommended: Inorganic pre-coated panels or electrolytic steel panels.

Key points: X-ray shielding and antibacterial coating optional.

Focusing solely on unit price, ignoring total life-cycle cost

Low-priced sandwich panels are prone to deformation, and sealing strips age quickly, leading to air leakage and an increase in energy consumption of over 30% later.

Lgnoring climate differences

Southeast Asia and coastal areas require aluminum-zinc coated substrates and moisture-proof core materials; otherwise, corner corrosion will occur within three years.

Using Outdated Standards

For new projects, please directly refer to ISO 14644-4:2022, eliminating non-airtight structures listed in the old appendices.

Cleanroom wall panels are not as simple as just buying and installing them. The correct selection process is: Process requirements → Technical parameter table → Third-party fireproof/mildew-proof test report → On-site airtightness sampling inspection → Maintenance manual archiving.

For multinational projects, it is recommended to prioritize suppliers with ISO 9001 and international cleanroom engineering performance records (e.g., Yirong sandwich panel manufacturer) to ensure that all factories in different locations adhere to the same acceptance standards.