Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

In 2025, when the European Union's CEAP includes the recycling rate of construction waste in member states' assessment indicators, a different scene is happening at the demolition site of an electronics factory in Berlin, Germany. The loader sorts and stacks the discarded rock wool fireproof board, and a professional team uses physical sorting technology to separate the metal keel from the rock wool core material. The latter is cleaned, crushed, and directly transported to the rock wool recycling factory. After 30 days, it is re pressed into new fireproof boards. This scene is a microcosm of the global construction industry's transition to a circular economy.

When "carbon neutrality" becomes a global consensus (136 countries have proposed carbon neutrality targets), the construction sector becomes a key battlefield for carbon reduction due to its contribution of 37% of carbon emissions. However, as the core material for fire prevention and insulation in industrial buildings (accounting for 42% of the global industrial fireproof material market), the contradiction between recyclability and environmental impact of rock wool fireproof board has long been ignored. Due to the complex fiber structure and difficulty in separating adhesives, over 90% of traditional rock wool sandwich boards are eventually buried or incinerated (EU Statistics Office 2023), generating 28 million tons of construction waste annually, equivalent to the weight of 1400 Eiffel Towers.

But today, technological breakthroughs and policy drivers are reconstructing the lifecycle value of rock wool fireproof boards. From disposable consumables to recyclable assets, it is not only a fire barrier, but also a key pivot for global carbon reduction. For users, choosing recyclable rock wool fireproof board is not only a compliance requirement for ESG investment, but also a strategic choice to seize the opportunity in the era of circular economy.

The environmental dilemma of traditional rock wool fireproof board lies in its linear mode of production, use, and disposal:

Production stage: Rock wool is mainly made of basalt and coke, melted at high temperature (above 1400 ℃) and centrifuged into fibers. The production of one ton of rock wool requires about 800kg of standard coal, with a carbon emission of 1.8 tons.

Usage stage: Although it has excellent fire resistance (A1 level non combustible), traditional rock wool fireproof panels require additional wrapping of waterproof film or metal foil due to fiber scattering and high moisture absorption (water absorption rate>3%), which increases the amount of adhesive used (accounting for 15% -20% of the board weight), making it difficult to separate after disposal.

Abandoned stage: In landfills, rock wool fibers take hundreds of years to degrade and release methane (greenhouse effect is 28 times that of CO ₂). During incineration, incompletely burned fibers can produce dioxins (strong carcinogens), polluting soil and water sources.

But the innovation of global enterprises and research institutions is breaking this dilemma:

1.1 Physical recycling technology

By using hot pressing and interface modification techniques, the fibers of discarded rock wool fireproof boards can be separated from the adhesive (separation rate>90%), and the cleaned fibers can be melted and regenerated into new rock wool boards. Experimental data from a German recycled material company shows that the fire resistance (A1 level) and physical strength (compressive strength ≥ 40kPa) of recycled rock wool board are consistent with those of virgin board, reducing production costs by 25%.

1.2 Chemical regeneration technology

In response to the problem of traditional rock wool fibers being difficult to decompose due to their silicate structure, global chemical giants such as BASF and Dow have developed acidic solution dissolution and ion exchange technologies, which can convert rock wool fibers into re polymerized siloxane monomers and synthesize new rock wool fibers. Research from the Norwegian University of Science and Technology shows that this technology can increase the number of cycles of rock wool to more than 5 times and reduce carbon emissions by 40% compared to native boards.

1.3 Composite structure design

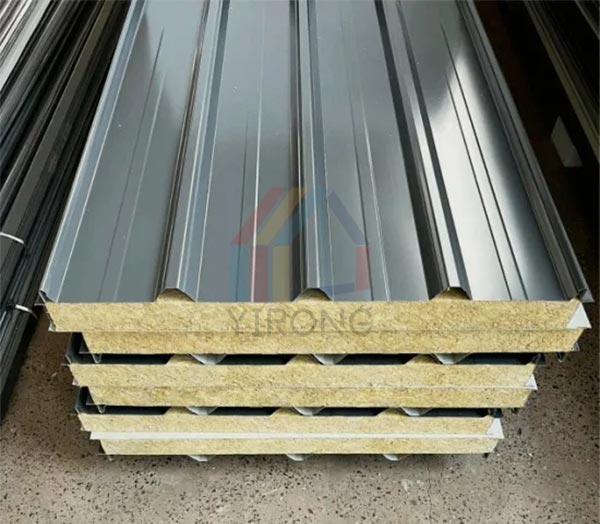

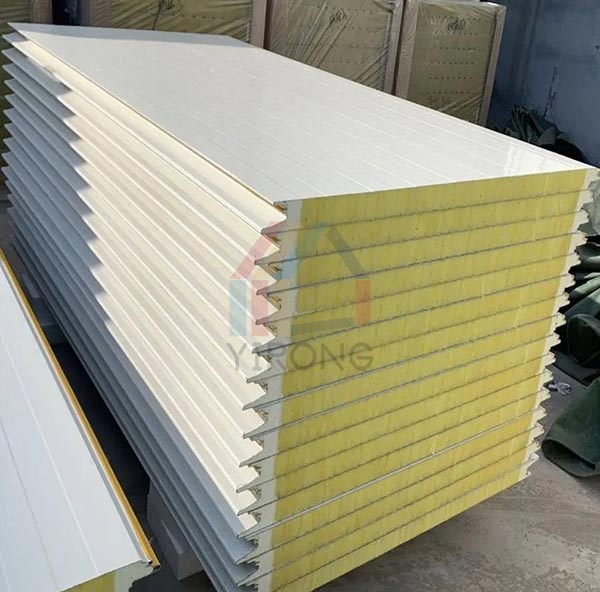

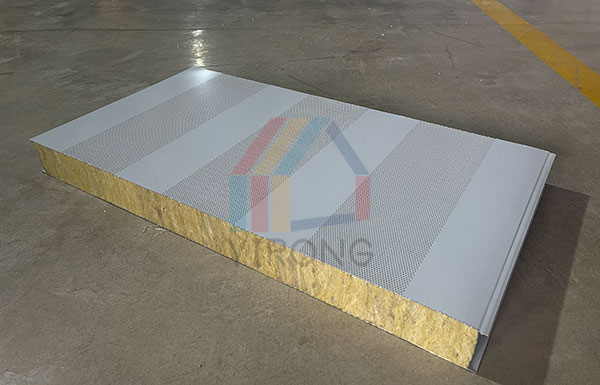

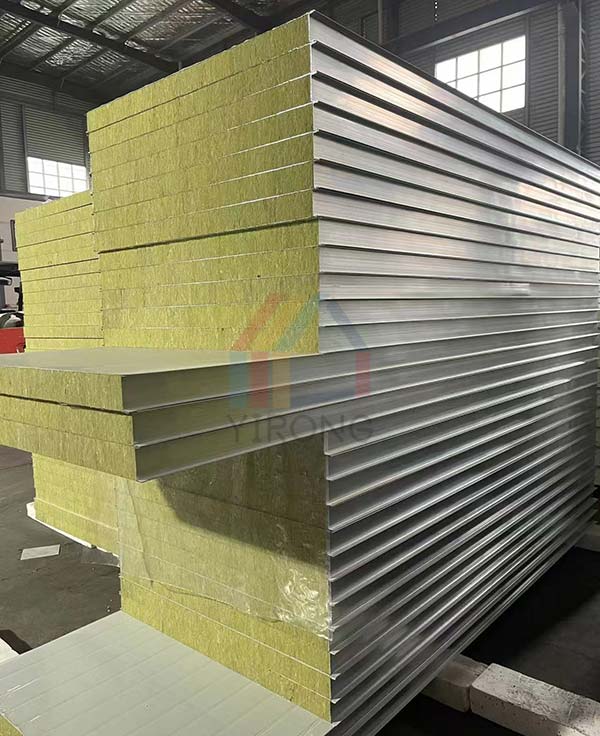

By using adhesive free composite technologies such as hot pressing bonding and mechanical locking, rock wool boards can eliminate their dependence on chemical adhesives. For example, the rock wool and aluminum magnesium manganese alloy composite board launched by Yirong Sandwich Panel is fixed by a physical interlocking structure and can be directly peeled off when discarded. The rock wool recovery rate has increased from the traditional 30% to 90%, and the aluminum magnesium manganese alloy recovery rate has reached 95% (traditional processes only 50%).

Choosing recyclable rock wool fireproof board is essentially reducing the burden on the entire life cycle of the building. The impact on the environment from production to disposal can be quantified into the following three sets of data:

2.1 Production stage

Traditional rock wool production has high energy consumption due to high-temperature melting, with a carbon emission intensity of 1.8 tons of CO ₂/ton. The new rock wool production line using electric melting furnace and waste heat recovery technology (such as Yirong's green factory) reduces energy consumption by 30% and carbon emissions by 1.2 tons of CO ₂/ton (33% less than traditional processes). If 50% of the global rock wool production capacity is upgraded to this technology, it can reduce CO ₂ emissions by about 12 million tons per year, equivalent to the annual carbon sequestration of 6 million hectares of forests.

2.2 Use phase

The fireproof performance of rock wool (Grade A1) makes it unnecessary to add additional flame retardant, and it is corrosion resistant and anti-aging (service life ≥ 25 years). Compared with traditional fireproof materials (such as magnesium glass board, service life 10-15 years), it can reduce the replacement frequency by 50%. Taking a 300000 square meter industrial plant as an example, the use of recyclable rock wool fireproof board does not require replacement within 25 years, reducing adhesive usage by 150 tons (reducing VOCs emissions), reducing construction waste by 2000 tons, and reducing landfill land by 1000 square meters.

2.3 Abandonment stage

After traditional rock wool sandwich boards are discarded, 90% are buried (occupying land) or burned (releasing pollutants). The recovery rate of recyclable rock wool board can reach 90%. For every ton of rock wool recovered, 1.5 tons of sand and gravel mining can be reduced (replacing natural aggregates), and 0.8 tons of standard coal consumption can be reduced (reducing CO2 emissions by 2 tons). If the penetration rate of recyclable rock wool fireproof board in global industrial buildings increases from the current 5% to 30% (2030 target), it can reduce 12.6 million tons of construction waste annually, equivalent to closing three medium-sized landfills.

The dual drive of policy and market is accelerating the transformation of rock wool fireproof board towards recyclability:

EU: The Green Deal requires all public buildings to use recyclable materials by 2030, with a recycling rate of over 80% for rock wool fireproof boards (currently only 30%).

China: The 14th Five Year Plan for the Development of Circular Economy specifies that by 2025, the comprehensive utilization rate of industrial solid waste will reach 55%, and rock wool will be included in the list of key renewable resources.

United States: LEED v5 certification increases the weight of material recyclability to 20%, and buildings using recyclable rock wool panels can receive an additional 15 points (out of a total of 110).

ESG investment: The global scale of ESG funds has exceeded $40 trillion, and the valuation premium of recyclable rock wool sandwich panel construction assets is 10% -15% (Bloomberg 2024).

For global users, choosing recyclable rock wool fireproof board is not only a compliance requirement, but also the key to reducing long-term costs:

Cost savings: The regeneration cost of recycled rock wool sandwich panel is 20% -25% lower than that of original board, and it can save 30% of material procurement costs within 20 years of use.

Asset appreciation: Rock wool buildings with high recyclability are more likely to obtain green loans (with interest rates lower by 0.5% -1%), resulting in a 15% increase in asset liquidity.

Brand premium: Disclosure of rock wool recyclability practices in ESG reports can increase a company's sustainability score (such as MSCI ESG) by 0.2-0.5 points.

From the first invention of rock wool for building fire prevention in 1860, to the global penetration rate of recyclable rock wool boards exceeding 30% by 2025, this breathable fire-resistant material is leveraging its recyclability as a pivot to drive the carbon reduction revolution in the construction industry.

For global users, choosing Yirong sandwich panel's recyclable rock wool fireproof board is not only choosing a material, but also choosing a sustainable development model that is environmentally responsible and invests in the future. When every piece of rock wool can be revitalized after demolition, and every industrial building becomes a node of circular economy, we have never been so close to the vision of a "zero carbon earth".