Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Under the triple pressures of fluctuating global energy prices, stricter environmental regulations, and rising labor costs, warehouse and factory owners are facing a common challenge: how can they spend less during construction and save more during operation?

As traditional building solutions are gradually phased out due to high energy consumption, short lifespans, and high maintenance costs, insulated sandwich panels, with their optimal lifecycle costs, are becoming a universal solution for cost reduction and efficiency improvement in industrial buildings worldwide.

From North American cold chain warehouses to Southeast Asian electronics factories, from European logistics centers to Middle Eastern manufacturing bases, this lightweight, high-energy building material is proving the value proposition: spending 10% more upfront can save 50% later—the true cost-saving logic.

Building materials and construction often account for 40%-60% of the total cost of industrial building construction. In traditional solutions, some owners opt for a single-layer color-coated steel plate with insulation added later to reduce initial investment, but they overlook two hidden costs.

Structural hazards: Single-layer color-coated steel plate has weak load-bearing properties, requiring additional steel trusses or supporting structures, increasing steel usage by 15%-20%.

Wasted construction time: The insulation layer must be installed in stages (first installing the steel plate, then filling it with insulation), extending the construction period by 20%-30% and increasing labor and management costs.

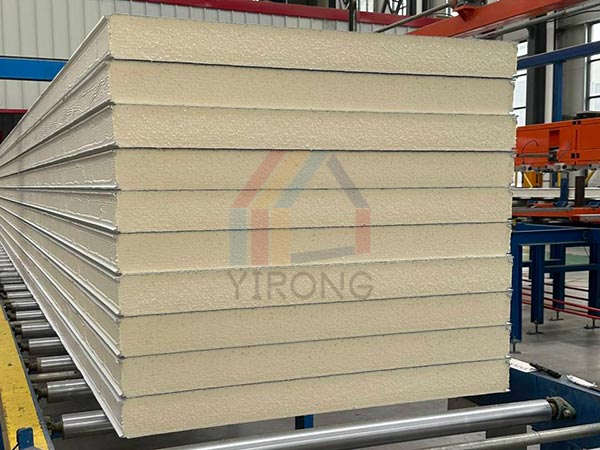

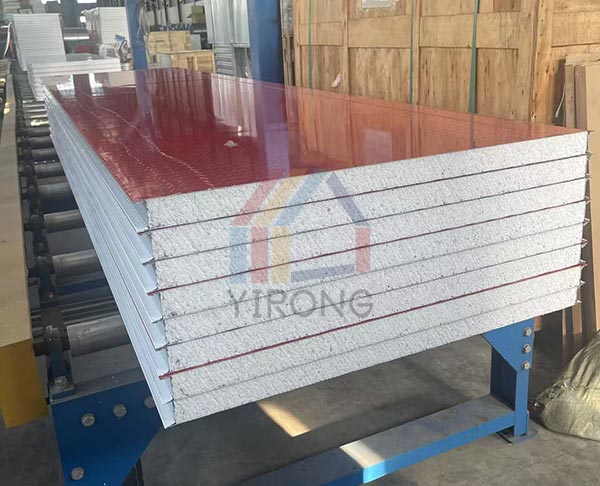

The integrated design of insulated sandwich panels directly solves this dilemma. The metal face sheet (galvanized steel/aluminum-magnesium-manganese) and core material (polyurethane/rock wool/glass wool) are composited and formed in a single step on a continuous production line, eliminating the need for secondary insulation installation. Taking the globally mainstream 100kg/m³ density polyurethane sandwich panels as an example, a thickness of only 50-100mm can achieve the same insulation performance as traditional steel panels and 500mm rock wool (thermal conductivity ≤ 0.024W/(m·K)), while reducing steel usage by 30% and shortening the installation process by 40%.

Case Study: A food warehouse project in Texas, USA, originally planned to use single-layer color-coated steel panels with post-filling, with a total budget of US$850,000. After switching to polyurethane sandwich panels, initial material and construction costs were reduced to US$920,000 (only an 8% increase). However, due to a 15-day reduction in construction time (saving US$120,000 in labor and management costs) and a reduction in structural loads, the foundation cost was reduced by US$50,000, resulting in a 10% reduction in total costs.

Energy consumption in industrial buildings accounts for as much as 30%-50% of total costs, and insulation performance directly determines the operating load of HVAC equipment (air conditioning, heating, and ventilation systems). The low heat transfer coefficient and high air tightness of insulated sandwich panels can dramatically reduce energy costs in warehouses and factories.

Cold chain warehouses: Data from a North American fresh produce storage project shows that the use of sandwich panels made of double-sided galvanized steel and a polyurethane core (100mm thick) reduced winter heating energy consumption by 42% and summer cooling energy consumption by 37%, resulting in annual electricity savings of over $120,000 (based on a local electricity price of $0.15/kWh).

Constant temperature workshops: A German precision instrument manufacturer uses rock wool sandwich panels (fireproof grade A1, thermal conductivity 0.038 W/(m·K)). Combined with a fresh air system, the workshop's temperature fluctuations have narrowed from ±5°C to ±1°C, equipment failure rates have dropped by 25%, and annual maintenance costs have been reduced by €80,000.

Factories in Humid and Hot Regions: Electronics assembly plants in Southeast Asia use aluminum-magnesium-manganese panels and polyurethane core materials (resistant to humidity and heat for ≥25 years). This avoids the problem of insulation peeling caused by rust in traditional color-coated steel panels, reduces air conditioning operation time from 16 hours per day to 10 hours per day, and saves over $6,000 in monthly electricity bills.

Core Logic: The one-time investment in insulating sandwich panels quickly pays for itself through annual energy savings. Based on the global average industrial electricity price of $0.12-0.20/kWh, the payback period for 80mm thick polyurethane sandwich panels is typically 2-3 years (depending on regional climate and energy intensity), with net returns for over 20 years of use.

Industrial buildings are typically required to have a service life of 20-30 years, but traditional materials often fail prematurely due to corrosion, aging, and improper maintenance, resulting in unaffordable construction. The durable design of insulated sandwich panels, from materials to structure, significantly extends the building's lifespan and reduces ongoing maintenance costs.

Corrosion Resistance: Panels are constructed using hot-dip galvanized steel (zinc layer thickness ≥ 275g/㎡) or aluminum-magnesium-manganese alloy (natural corrosion resistance life ≥ 50 years), offering protection against industrial exhaust, salt spray (e.g., in coastal areas), and chemical corrosion (e.g., in chemical parks).

Stable Core Material: The polyurethane core material has a closed-pore ratio of ≥ 90% and a water absorption rate of ≤ 1% (water absorption of rock wool core material after waterproofing treatment is ≤ 3%), preventing thermal insulation degradation due to moisture absorption. Traditional rock wool panels can increase their thermal conductivity by 20%-30% after 10 years.

Structural Durability: The sandwich panels utilize a continuous roll-forming process, achieving a bond strength of ≥ 0.1MPa between the metal panels and the core material (far exceeding the industry standard of 0.06MPa). They can withstand wind speeds of 120km/h (equivalent to a Category 11 typhoon) or snow loads of 50kg/㎡, reducing repair costs associated with structural damage.

Comparative Data: A UK logistics center, built 20 years ago with a traditional color-coated steel plate + rock wool structure, required three major overhauls within 10 years (totaling £180,000) due to moisture absorption in the core material and rust on the steel plates. Meanwhile, another warehouse, built around the same time, used polyurethane sandwich panels and has undergone only one routine maintenance session (costing £20,000). Its overall residual value is 30% higher.

Building requirements vary significantly across different regions of the world. North America requires hurricane resistance, Europe requires fire protection, the Middle East is sensitive to high temperatures, and Southeast Asia requires moisture resistance. Through customized materials and process adaptation, insulated sandwich panels can provide the optimal cost solution for each region.

For cold regions (such as Canada and Northern Europe): A high-density polyurethane core (≥40 kg/m³) combined with double-layer metal panels (with a moisture-proof membrane sandwiched between them) is used. The thermal conductivity is as low as 0.022 W/(m·K). This thermal insulation design (insulating gaskets between the keel and the main structure) reduces energy consumption caused by thermal bridging.

In hot and humid regions (such as Indonesia and Brazil): Use aluminum-magnesium-manganese panels (salt spray corrosion resistant) with a rock wool core (hydrophobic treatment). A core density of 120 kg/m³ or higher is recommended to prevent expansion and deformation caused by high temperature and humidity.

In regions with high fire protection requirements (such as Japan and Australia): Use rock wool or glass wool core (fire resistance class A1). Apply fire-retardant coating (compliant with EN 14509) to the metal panels, meeting both building regulations and insurance company requirements for low premiums.

In regions requiring modularity (such as temporary warehouses in the Middle East and infrastructure camps in Africa): Provide standardized sandwich panel components (600-1200 mm in width, customizable in length). These components are plug-and-install, offering installation efficiency five times higher than traditional construction, significantly reducing labor and transportation costs.

For warehouse and factory owners, saving money is never about choosing the cheapest material; it's about choosing the solution with the lowest overall lifecycle cost. The value of insulated sandwich panels lies in the fact that a 10% increase in upfront investment yields a 50% reduction in energy consumption, a 30% reduction in maintenance, and a 20-year durability guarantee. This not only optimizes construction costs but also enhances business competitiveness.

With global energy prices remaining high and environmental regulations becoming increasingly stringent, choosing insulated sandwich panel is essentially buying inflation insurance for a company's future. After all, in the industrial construction industry, savings are the real competitive advantage.