Zhengzhou, Henan Province, China

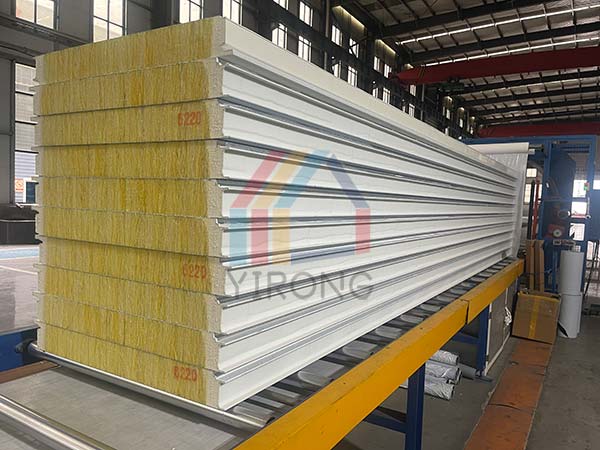

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

In the field of building and industrial insulation, PU edge rock wool board (Polyurethane-Edge Rockwool Panel) and Rockwool Sandwich Panel are common insulation and fireproof materials, but they have significant differences in structure, performance, and application. This article will help users make clear choices from the perspectives of core differences, performance comparisons, applicable scenarios, cost, and environmental friendliness.

Comparison Item | PU-Edged Rockwool Panel | Rockwool Sandwich Panel |

|---|---|---|

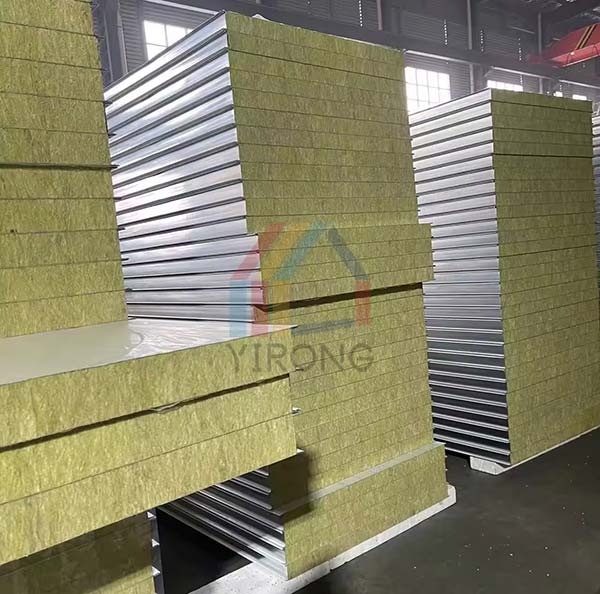

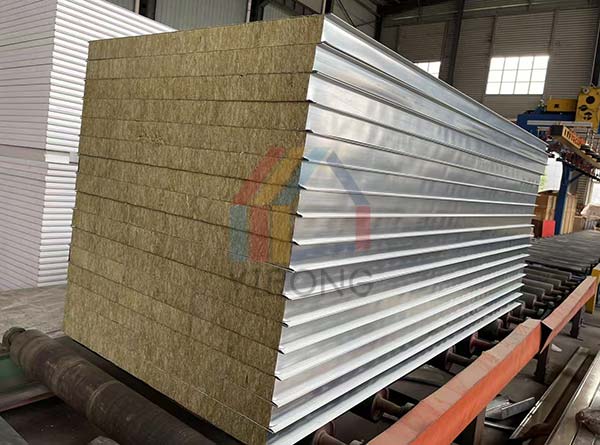

Structure | Rockwool core + double-sided color steel plates with PU (polyurethane) edges sealed | Rockwool core + double-sided color steel plates fully bonded |

Edge Sealing | Only edges sealed with PU to enhance moisture resistance and structural strength | Fully bonded via adhesives or foaming processes, integrating rockwool with steel plates |

Rockwool Arrangement | Rockwool fibers vertically or horizontally aligned; PU edges reinforce integrity | Rockwool fibers randomly distributed; fixed by overall bonding |

Key points:

The edges of PU edge sealing rock wool board are sealed with polyurethane (PU), which has stronger moisture resistance and deformation resistance, and is suitable for high humidity or extreme climate environments.

Rock wool sandwich panel is an integral bonding structure, with rock wool and color steel plate bonded more tightly, but without additional protection at the edges, and slightly weaker moisture resistance.

(1) Thermal insulation

Both use rock wool core material (with low thermal conductivity and excellent insulation), but PU edge sealed rock wool board has slightly higher overall insulation efficiency due to lower thermal conductivity at the PU edge.

The insulation performance of rock wool sandwich panels is stable, but if the bonding process is poor, it may affect the overall insulation effect.

(2) Fire resistance performance

Both belong to Class A non combustible materials (rock wool itself is non combustible) and comply with global building fire protection standards (such as EU EN 13501 and US ASTM E84).

PU edge sealing does not affect the fire rating, but PU itself is flammable (although the edge sealing layer is very thin, overall it still belongs to Class A).

(3) Moisture proof and waterproof

The polyurethane edge sealing of PU edge rock wool board has excellent waterproof properties and is suitable for humid areas such as beaches and high humidity factories.

If the rock wool sandwich panel is poorly sealed, it may absorb moisture and affect insulation, requiring additional moisture-proof treatment.

(4) Structural strength&deformation resistance

PU edge sealed rock wool board enhances the overall rigidity of the board, with stronger resistance to bending and impact, making it suitable for large-span roofs or exterior walls.

The rock wool sandwich panel structure is stable, but if transported or installed improperly, it may deform due to unprotected edges.

Application Scenario | Recommended Panel | Reason |

|---|---|---|

Humid environments (coastal areas, high-humidity factories) | PU-edged rockwool panel | PU edges prevent moisture absorption, ensuring long-term performance. |

High-temperature industrial plants (steel, chemical) | Both | Rockwool resists high temps; PU edges add edge anti-deformation. |

Standard building exteriors/roofs (offices, residences) | Rockwool sandwich panel | Cost-effective with sufficient insulation. |

Large-span structures (stadiums, warehouses) | PU-edged rockwool panel | Better anti-deformation for long-term load-bearing. |

Ultra-fire-sensitive areas (data centers, hospitals) | Both (Class A) | PU-edged panels offer tighter edge sealing for added fire reliability. |

(1) Price comparison

PU edge sealing rock wool board has a more complex edge sealing process, and its cost is about 10-20% higher than that of rock wool sandwich board.

The production process of rock wool sandwich panel is mature, the price is more economical, and it is suitable for projects with limited budgets.

(2) Environmental friendliness

Rock wool: Made from natural ore (basalt), recyclable, and environmentally friendly.

PU (polyurethane) edge banding: Although slightly less environmentally friendly (combustion may release harmful gases), the edge banding layer is very thin and has a relatively small overall impact.

Trend: The EU, North America and other regions have strict fire and environmental standards for PU, and high-quality PU edge banding boards comply with international environmental certifications such as REACH and RoHS.

Choose PU edge sealing rock wool board, if:

✅ Damp environment (seaside, high humidity areas)

✅ Need for higher deformation resistance (large-span roofs, heavy-duty factories)

✅ Long term use, pursuing better durability

Choose rock wool sandwich panel, if:

✅ Limited budget, pursuing cost-effectiveness

✅ Ordinary building insulation (office buildings, residential buildings)

✅ Standard fire protection requirements, no extreme environmental requirements

PU edge sealing rock wool board is a high-end choice, suitable for harsh environments (humid, large-span, high durability requirements), with a slightly higher price but more durable.

Rock wool sandwich panel is economical and practical, suitable for most conventional building insulation, with high cost-effectiveness and easy installation.

No matter which one is chosen, the A-level fire resistance and insulation performance of rock wool itself can meet global building standards, with the key being edge treatment, environmental adaptability, and budget.