Zhengzhou, Henan Province, China

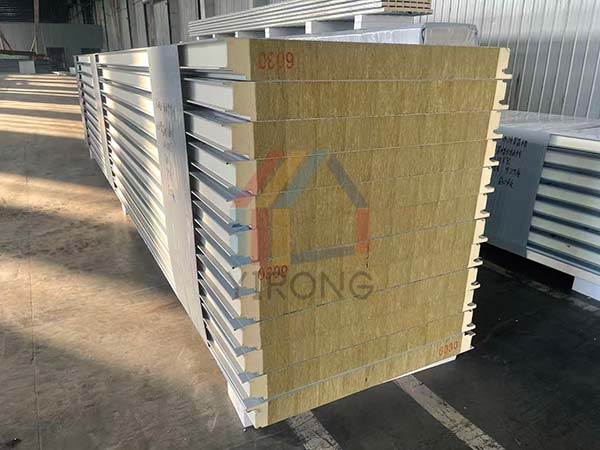

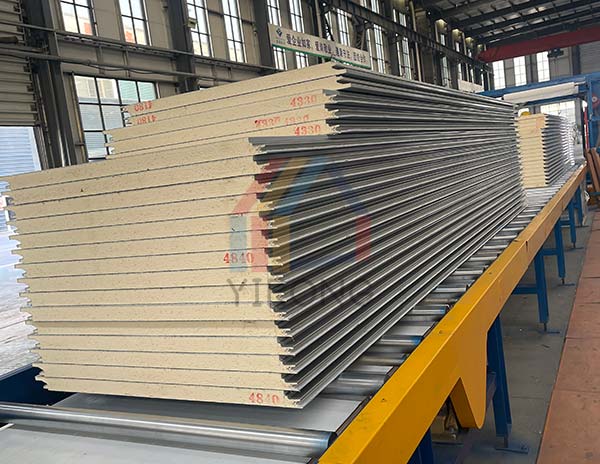

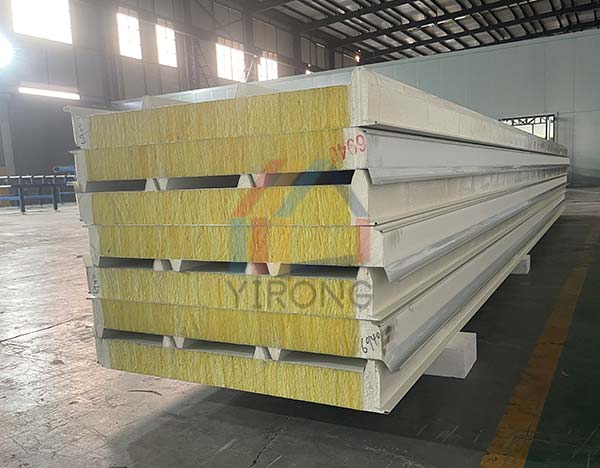

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Driven by both the "dual carbon" goals and the energy crisis, building energy conservation has become a global consensus. Data shows that global building energy consumption accounts for 36% of total social energy consumption, with heat loss from exterior walls accounting for over 40% of total building energy consumption. Against this backdrop, metal insulation boards, with their dual advantages of insulation and protection, have stood out among numerous building materials. The global market size for metal insulation board is projected to exceed US$35 billion by 2025, with an application rate exceeding 55% in new buildings in Europe, America, and the Asia-Pacific region, making it a core material driving building energy conservation.

Metal insulation boards are composed of a metal panel (color-coated steel plate, aluminum-magnesium-manganese plate, etc.) and an insulation core material (polyurethane, rock wool, etc.). Their energy-saving capabilities stem from the perfect integration of structural design and material properties. Their core advantages are reflected in three dimensions:

1. Ultimate Insulation

Insulation performance is a core indicator for measuring energy-saving materials. The composite structure of metal insulation boards achieves an insulation effect of "1+1>2". In 2024, the thermal conductivity of mainstream products was as low as 0.022-0.030 W/(m·K), only 1/10 of that of traditional brick walls. Taking a 1000㎡ office building as an example, using metal insulation panels for the exterior walls can reduce heating and cooling energy consumption by approximately 12,000 kWh per year compared to traditional brick walls, equivalent to a reduction of 9.6 tons of carbon dioxide emissions.

For different climate zones, metal insulation panels can be flexibly combined with core materials: polyurethane core materials are used in cold regions such as Northern Europe and Canada, improving insulation efficiency by 20%. In tropical regions such as Southeast Asia and the Middle East, water-repellent rock wool is used, balancing insulation and moisture resistance, solving the energy-saving failure problem of traditional materials due to high-temperature moisture absorption.

2. Durability and Damage Resistance

The value of building energy conservation lies not only in short-term energy savings but also in long-term stable performance output. The metal panels of the metal insulation boards are treated with a fluorocarbon (PVDF) coating, providing excellent weather resistance. It does not crack in temperatures as low as -40°C in Northern Europe and does not fade under the scorching sun of 50°C in the Middle East, boasting a lifespan of 25-30 years, more than twice that of traditional insulation materials.

A 2025 industry report shows that buildings using metal insulation panels experience only a 5%-8% decline in insulation performance after 20 years, while traditional polystyrene board buildings experience a decline of over 30%. This long-term performance makes it highly favored in the renovation of existing buildings worldwide. In San Francisco, USA, the use of metal insulation panels to renovate old buildings resulted in a 35% reduction in annual energy consumption per building.

3. Integrated and High-Efficiency

Metal insulation boards enable integrated construction through factory prefabrication and on-site assembly, eliminating the need for separate insulation and finishing work as with traditional materials, shortening the construction period by more than 50%. In an industrial plant project in Munich, Germany, the construction of 12,000 square meters of exterior walls was completed in just 18 days, saving 40% in labor costs compared to traditional methods.

Meanwhile, its lightweight properties reduce building load, decreasing the amount of steel used in the main structure by 8%-12%, further reducing the building's life-cycle cost. This dual attribute of energy saving and cost reduction has led to its rapid adoption in developing country markets; India, Vietnam, and other countries have seen an average annual growth of 28% in metal insulation board imports in recent years.

In recent years, global technological innovation has continuously strengthened the core energy-saving position of metal insulation boards, achieving breakthroughs in multiple dimensions, from material improvement to functional integration:

1. Environmentally Friendly Core Material Replacement, Balancing Energy Saving and Ecology

Traditional polyurethane core materials' foaming agents once posed environmental risks. By 2024, major global companies had fully adopted fluorine-free foaming technology, reducing the ozone depletion potential (ODP) of insulation boards to 0 and the global warming potential (GWP) to 90%, fully complying with the EU's Fluorine Gas Regulation and China's "dual carbon" requirements.

Bio-based core materials are emerging as a new trend. A Dutch company has developed a bio-based polyurethane core material made from agricultural waste. This material not only maintains its insulation performance but is also 100% biodegradable, achieving the highest rating in the European Green Building Certification (BREEAM).

2. Functional Integration, Expanding Energy-Saving Boundaries

Metal insulation panels are upgrading from single-function insulation to multi-functional energy-saving solutions. A photovoltaic-integrated metal insulation panel, launched in 2025, integrates solar panels with the insulation board, achieving both external wall insulation and power generation with an efficiency of 18%-22%. After adopting this product, an industrial park in Shandong, China, met 15% of its electricity needs with external wall power generation, saving over 2 million yuan annually in electricity costs.

Furthermore, new products such as self-cleaning metal insulation boards and temperature-regulating metal insulation panels are appearing on the market. The former uses a nano-coating to reduce dust adhesion and ensure efficient heat dissipation from the external wall. The latter utilizes phase change materials to automatically regulate indoor temperature, further reducing air conditioning energy consumption.

3. Intelligent Monitoring for Enhanced Energy Efficiency

European and American companies have begun embedding wireless sensors into metal insulation panels to monitor panel temperature, humidity, and insulation performance degradation in real time, synchronizing data to a cloud platform. When insulation performance declines by more than 10%, the system automatically issues an alert, enabling proactive maintenance. This intelligent monitoring technology makes building energy efficiency controllable and has been widely applied in high-end buildings in Singapore and Dubai.

The energy-saving advantages of metal insulation boards have been validated in various scenarios globally, becoming a cross-industry energy-saving solution:

- Industrial Buildings: In scenarios such as automobile factories and cold storage facilities, metal insulation panels can meet constant temperature requirements. A Mercedes-Benz factory in Germany uses rock wool core metal insulation panels, maintaining a constant workshop temperature of 20°C in winter and reducing heating energy consumption by 42%.

- Public Buildings: Metal insulation panels are used in large-space buildings such as airports and high-speed rail stations, balancing energy efficiency and aesthetics. The new Istanbul Airport in Turkey uses aluminum-magnesium-manganese panel insulation panels, saving over $12 million annually in air conditioning electricity costs.

- Residential Buildings: In the residential sector, metal insulationboards have solved the traditional problem of "cold bridging" in exterior walls. After adopting this product in affordable housing projects in northern China, residents saw a 30% reduction in winter heating costs. In Japan and South Korea, its application rate in multi-family housing has exceeded 40%.

The emergence of metal insulation boards as a core component of building energy conservation is the result of combined advancements in material performance, technological upgrades, and global policies. In the future, as ultra-low energy buildings become the global mainstream, metal insulation panels will evolve towards lighter, thinner, more environmentally friendly, and smarter designs. The comprehensive application of bio-based materials, the improved efficiency of photovoltaic integration, and deep integration with smart building systems will enable them to play an even more important role in global building energy conservation. For global users, choosing metal insulation panels means choosing a long-term, economical, and sustainable energy-saving solution—this is its core value.