Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

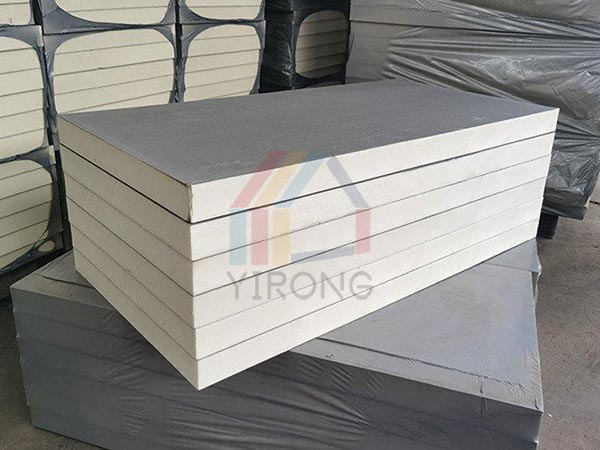

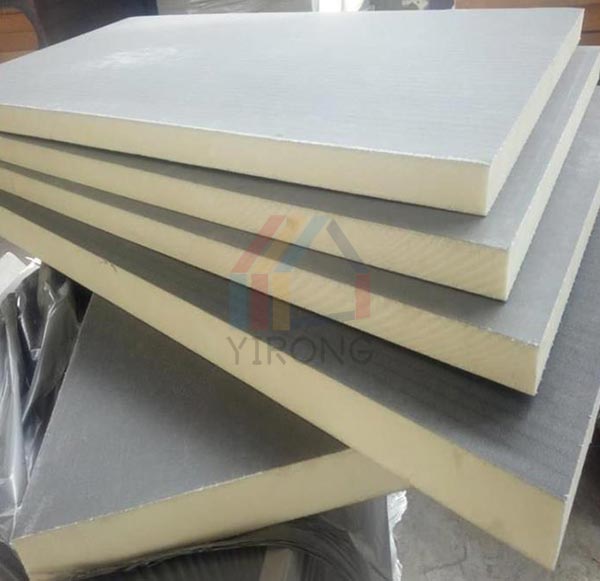

PIR (polyisocyanurate) wall panels, with their ultra-low thermal conductivity, Class A fire resistance, and lightweight yet high-strength properties, are rapidly replacing traditional insulation materials. According to Global Market Insights, the global PIR insulation market reached $8.5 billion in 2023, with an annual growth rate exceeding 7%. Passive houses in Europe, North American green policy projects, and high-rise buildings in Asia all prioritize PIR.

Environmental Upgrades: The EU REACH regulation restricts fluorinated foaming agents, promoting the widespread adoption of water-based/hydrofluoroolefin (HFO) formulations.

Smart Construction: BIM technology enables precise PIR sandwich panel layout, and robotic cutting improves construction accuracy.

Circular Economy: The application rate of recyclable PIR wall panels have exceeded 30% in pilot projects in the Netherlands and Germany.

Error Control: Wall flatness deviation ≤3mm/2m; otherwise, cement mortar leveling is required.

Cleanliness and Drying: Thoroughly remove oil and dust; moisture content <8%; infrared humidity meter detection.

Essential for a moisture barrier: A vapor barrier membrane (such as PE membrane) must be pre-laid in basements or high-humidity environments, with an overlap width ≥100mm.

Case Study: A data center in Northern Europe experienced condensation on PIR boards due to dampness in the subfloor, increasing maintenance costs by 40%.

Staggered Installation: Adjacent boards should have longitudinal and transverse joints staggered by ≥200mm to avoid thermal bridging.

Triple Sealing Protection:

Seams are filled with specialized polyurethane foam sealant.

Covered with waterproof tape (butyl rubber).

Outer layer sprayed with elastic sealant (such as silicone sealant).

Corner Reinforcement: L-shaped metal corner protectors are used at door and window openings to prevent stress cracking.

| Spacing Requirement | ||||

| Low-rise buildings (≤10m) | Plastic expansion bolts + self-tapping screws | ≤600mm×600mm | ||

| Stainless steel backing plates + mechanical anchors | ≤400mm×400mm | |||

| Curved walls | Custom curved clips + flexible connectors | Adjusted according to curvature |

Open Flame Prohibition: Although PIR wall panels are flame-retardant (B1 grade), non-sparking tools must be used when cutting; oxy-acetylene welding is strictly prohibited.

Ventilation Requirements: Explosion-proof fans are mandatory in enclosed spaces; VOC concentration <50ppm.

Standard PPE Equipment: N95 mask, cut-resistant gloves, and safety goggles.

German Passive House Standard (PHI): Requires thermal imaging inspection of PIR sandwich panel joints with a ΔT ≤ 0.5℃.

Singapore BCA Green Certification: Mandates the use of HFO foamed PIR panels (GWP value < 1) to reduce carbon footprint.

US ICC-ES Certification: Anchoring systems must pass ASTM E330 wind load testing, simulating a 160km/h hurricane.

AR-Assisted Positioning: Workers wearing HoloLens glasses can view panel layout and pipeline conflict points in real time.

Drone Inspection: After completion, infrared thermal imagers scan the entire wall, automatically generating an airtightness report.

Modular Prefabrication: Factory pre-assembles PIR wall panels and a keel frame, increasing on-site hoisting efficiency by 300%.

The superior performance of PIR wall panels must be realized with millimeter-level installation precision. Choosing an ISO 9001 certified construction team, adhering to local standards (such as China's GB/T 20974 and the EU's EN 13165), and embracing digital tools are essential to transforming material advantages into value throughout the building's entire lifecycle.