Zhengzhou, Henan Province, China

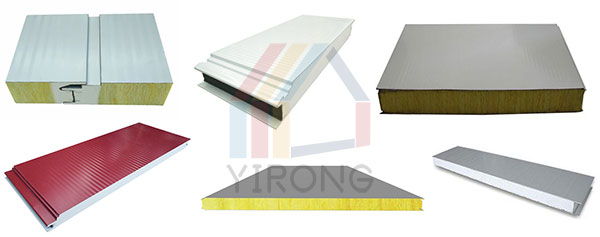

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

In warehouse design, internal partition boards are central to functional zoning. They impact storage efficiency, employee safety, and long-term operating costs. Choosing the wrong material can lead to leaks, fire risks, or frequent repairs.

The primary selection criterion for partition board is their intended use, as different areas have vastly different requirements:

Storage Area (Shelving): Requires low-cost, easy-to-install partitions. Gypsum board is the preferred choice (30% lower cost), but only suitable for dry environments.

Office/Control Area: Requires sound insulation and aesthetics. Lightweight ALC (aerated concrete) panels are superior, offering 50% better sound insulation and achieving Class A fire resistance.

Sorting/Logistics Area: Requires high durability. Metal partitions (such as corrugated steel sheets) are highly impact-resistant, preventing damage from goods collisions.

Case Studies: The Duisburg logistics center in Germany used metal partition board in its sorting area, resulting in no repairs in ten years. A Tokyo warehouse in Japan used ALC panels to separate its office area, increasing employee satisfaction by 40%.

| Factor | Choose Logic | Recommended Materials | Tips |

| Budget | Low budget (<10/㎡) → gypsum board; Medium to high budget (>10/㎡) → gypsum board; Medium to high budget (>15/㎡) → ALC or metal plate. | Gypsum board (economical type) | Avoid using gypsum board in damp areas, otherwise it will mold within 3 years |

| Climate | Wet areas (annual humidity>70%) → Waterproof materials must be selected; Dry area (humidity<50%) → Gypsum board is acceptable | Metal partition board (waterproof) | The Southeast Asian warehouse once experienced water leakage due to the use of gypsum board, with repair costs exceeding $20000 |

| Fire safety requirements | Mandatory A-level fire prevention measures for warehouses (such as GB50016 in China and NFPA 221 in the United States). ALC board is naturally fire-resistant, and metal boards require fire-resistant coating. | ALC board (uncoated) | Materials that do not meet the standards may be stopped by the fire department |

| Installation speed | Complete the project within 4 weeks → Select prefabricated panels (such as ALC); Slow work and meticulous project → Gypsum board | Complete the project within 4 weeks → select prefabricated panels (such as ALC); Slow work and meticulous project → Gypsum board | The Texas warehouse in the United States uses ALC board, which is 50% faster than gypsum board |

| Material | Advantages | Disadvantages | Global Applications |

| Gypsum Board | Lowest cost ( $ 8-10/sqm); sound insulation; easy to cut | Not waterproof; prone to damage in humid areas | Dry climate offices (e.g., Middle East, northwest China) |

| Metal Partition | Waterproof, fire-resistant, impact-resistant; 20+ years lifespan | High cost ( $ 15-20/sqm); requires professional installation | High-humidity warehouses (e.g., Singapore, Brazil ports) |

| ALC Panel | Fire-resistant (Class A); lightweight and easy to install; sound insulation; eco-friendly | Moderate cost ( $ 12-18/sqm) | Mainstream choice (70% of industrial warehouses) |

Functional Positioning: First, divide the warehouse into areas (storage/office/logistics), then match materials accordingly.

Example: Shenzhen, China e-commerce warehouse: gypsum board for storage, ALC board for office, and metal panels for logistics.

Climate Data Check: Consider local humidity (e.g., Southeast Asia >80% → metal panels).

Fire Safety Standard Verification: Ensure materials have Class A certification (e.g., China CCC, EU CE).

Total Cost Calculation: Don't just look at the unit price! ALC boards are initially 10% more expensive, but save 40% on maintenance costs over 10 years.

Avoid the Low-Price Trap: A warehouse in Africa used inferior gypsum board, resulting in wall collapse after six months and a loss of $50,000.

Prioritize Precast Panels: ALC panels are assembled on-site, reducing construction time by 70%.

Warehouse partition boards are not chosen arbitrarily, but are a safe investment. Practice has proven that:

Metal panels are suitable for damp areas, while gypsum board is ideal for dry areas;

ALC boards are essential for high fire resistance requirements;

Total cost over 10 years is more important than the initial price.

Remember: Choosing the right partition board doubles warehouse efficiency. Choosing the wrong one creates hidden dangers.