Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

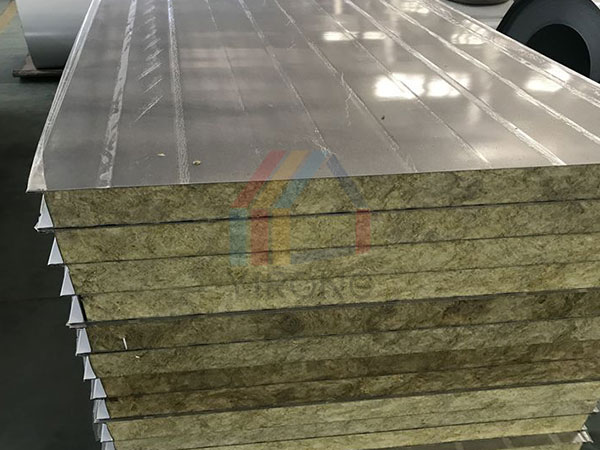

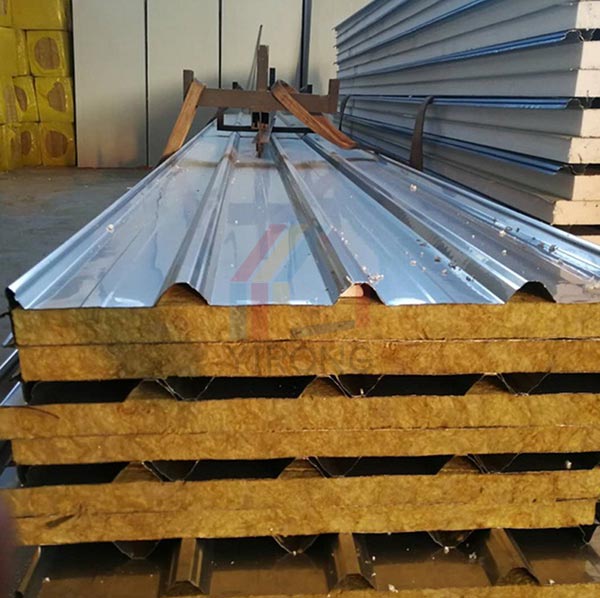

Stainless steel rock wool sandwich panels are widely used in industrial plants, commercial buildings, and cleanrooms due to their lightweight, high strength, and excellent fire resistance. However, determining their fire rating requires a combination of scientific methods and standardized procedures. The following is a globally accepted guide to help users quickly identify compliant products.

Fire Rating Certification

① International Standards: Must comply with ISO 1182 (non-combustible material certification) and EN 13501-1 (fire rating of building products).

② Chinese Standards: Determined as Class A1 (non-combustible material) according to GB 8624-2012. The report must clearly indicate the whole-panel test results of the composite structure of the metal panel and rock wool core.

Calorific Value and Combustion Performance

Calorific Value Threshold: The calorific value of the rock wool core material must be ≤2.0 MJ/kg (Class A1 standard). If it exceeds this, it is downgraded to Class B. Combustion Test: Take a 3cm x 3cm core material sample, ignite it with an open flame for 10 seconds, then remove it. The passing standard is self-extinguishing upon removal of the flame, no molten dripping, and only white smoke (black smoke or continuous burning indicates adulterated rock wool).

Smoke Density and Toxicity

① Smoke Density (Ds Value): Laboratory test requires ≤75 (GB/T 8627). On-site, the smoke can be covered with a white cloth; no black deposits indicate passing.

② Toxicity Test: The residue after combustion should be inorganic (such as silicon dioxide). Halogenated or combustible fibers are prohibited.

Fire Resistance Limit

Time Requirements: 100mm thick plate fire resistance limit ≥70 minutes (GB/T 9978), 150mm thick plate ≥120 minutes.

Visual and Tactile Inspection

① Edge Sealing Integrity: Check if the board seams are sealed with polyurethane. Unsealed or poorly sealed edges will shorten the fire resistance time by 30%.

② Core Material Uniformity: Tear open the edge and observe the cross-section. Rock wool fibers should be pale yellow and free of slag particles larger than 1mm in diameter.

Simple Testing Tools

① Water Drop Test: Drop water onto the board surface for 5 minutes. The water droplet should roll without penetrating (water absorption ≤1%).

② Coating Thickness: The metal panel coating must be >0.2mm and free of organic components; otherwise, the overall fire resistance may be reduced.

Third-Party Testing Report

Required Checks: Complete whole-board testing report (including calorific value, smoke density, and fire resistance time), and raw material traceability certificate (basalt content ≥80%).

Report Forgery

Beware of reports that only provide core material testing reports (excluding the panel) or reports without CMA/CNAS certification.

Material Adulteration

Slag adulteration will cause the calorific value to exceed the standard. This can be quickly verified using a calorific value tester (>2.0MJ/kg indicates a downgrade).

Low-Price Trap

Boards priced < $15/㎡ may use recycled cotton or low-density rock wool (actual density < 100kg/m³).

| Application Scenario | Recommended Thickness | Additional Requirements | |||

| General Factory Building | 100mm | ≥120kg/m³ | Polyurethane Sealing | ||

| Chemical Plant/Data Center | 150mm | ≥140kg/m³ | Surface Resistance ≤10⁶Ω (Anti-static) | ||

| Clean Room | 100mm | ≥120kg/m³ | No Organic Coating, Hydrophobicity Compliance |

International Certification: Prioritize products certified by FM, UL, or BS 8414.

Regular Testing: Randomly inspect 10% of the boards annually, focusing on edge sealing and smoke density changes.

Maintenance Points: Avoid mechanical damage to the board surface; in corrosive environments, apply an anti-corrosion coating every 3 years.

Through the above methods, users can systematically evaluate the fire resistance of stainless steel rock wool sandwich panels to ensure building safety compliance. For complete testing standards or manufacturer recommendations, please refer to GB/T 51379-2019 or contact a certification body for technical support.