Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

In the construction of modern industrial factories, the performance, durability and economy of the exterior wall cladding panels directly affect the service life and operating costs of the factory building. With the continuous emergence of new building materials, how to choose an exterior wall cladding panel that is both functional, safe and cost-effective has become the focus of attention of enterprises.

The exterior walls of factory buildings need to cope with complex environmental challenges, including extreme weather, fire protection requirements, thermal insulation, maintenance costs, etc. The ideal cladding panel must meet the following conditions:

1. High strength and weather resistance: resist wind pressure, rain erosion and ultraviolet aging.

2. Fireproof performance: comply with national building fire protection regulations (such as Class A fire resistance limit).

3. Thermal insulation: reduce energy consumption of factory buildings and adapt to different climate zones.

4. Easy installation: shorten construction period and reduce labor and time costs.

5. Economical efficiency: balance initial investment with long-term maintenance costs.

1. Color steel plate

Advantages: low price, light weight, flexible installation.

Disadvantages: easy to rust, poor fire resistance, and easy coating shedding after long-term use.

Applicable scenarios: short-term temporary buildings or dry areas.

2. Aluminum curtain wall

Advantages: lightweight, corrosion-resistant, and highly decorative.

Disadvantages: weak thermal insulation performance and high cost.

Applicable scenarios: parks with high aesthetic requirements or coastal high-humidity areas.

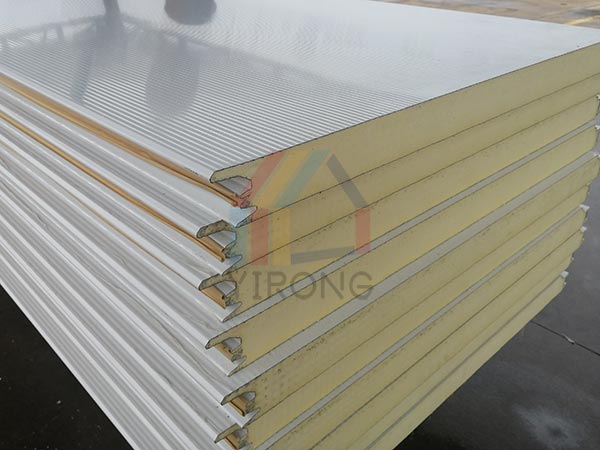

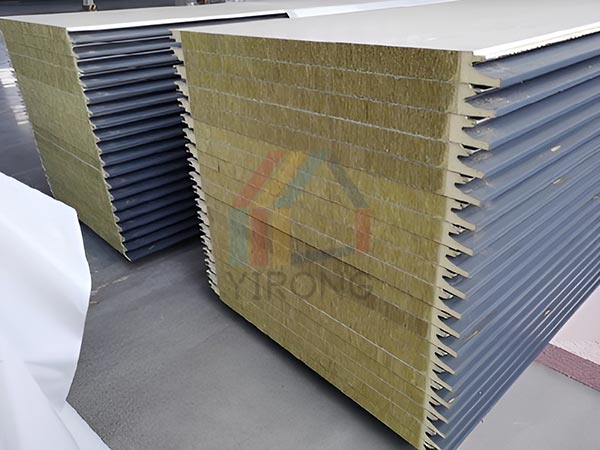

3. Metal sandwich panel (core recommendation)

Fire retardant: The core material uses A-level non-combustible materials such as rock wool and polyurethane foam, and the fire resistance limit can reach 1-3 hours.

Thermal insulation: The sandwich layer has low thermal conductivity and significant energy-saving effect.

Strong impact resistance: The composite structure of metal panel and core material has excellent wind pressure resistance.

Quick installation: Modular design reduces on-site construction pollution and time.

Outstanding economic efficiency: The service life is more than 20 years, and the maintenance cost is low.

Application cases: Automobile manufacturing plants, logistics warehouses, cold chain storage and other factories with high requirements for fire prevention and insulation.

1. Safety upgrade

For the dense working environment of the factory building, the A-level fireproof performance of the metal sandwich panel can effectively prevent the spread of fire and buy time for personnel evacuation. For example, in chemical plants, its corrosion resistance can also avoid chemical corrosion.

2. Energy saving and consumption reduction

The factory with polyurethane sandwich panels can reduce the air conditioning load by 20%-30% in summer and reduce heat loss by more than 15% in winter, helping enterprises achieve the "dual carbon" goal.

3. Comprehensive cost advantage

Although the unit price is about 30% higher than that of color steel plates, its extended life brings reduced maintenance costs (annual savings of 10%-15%), and the long-term cost performance is significant.

1. Climate adaptation: Galvanized metal panels are preferred in high humidity areas; the thickness of the insulation layer needs to be increased in extremely cold areas.

2. Compliance: Confirm that the panels comply with the building design fire protection specifications and local standards.

3. Supplier qualifications: Select brand manufacturers with ISO certification and third-party test reports.

4. Customized design: Supports processing requirements such as special-shaped cutting and window opening, and adapts to complex factory structures.

For factory building construction, exterior wall cladding panels are not only beautiful in appearance, but also core facilities related to safety and efficiency. Metal sandwich panels are gradually replacing traditional materials with their comprehensive advantages such as fire prevention, heat preservation, and durability, and have become the first choice for modern factory. During the site selection, material selection and construction stages, it is recommended to work with a professional design team to tailor a solution that combines performance and economy.