Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

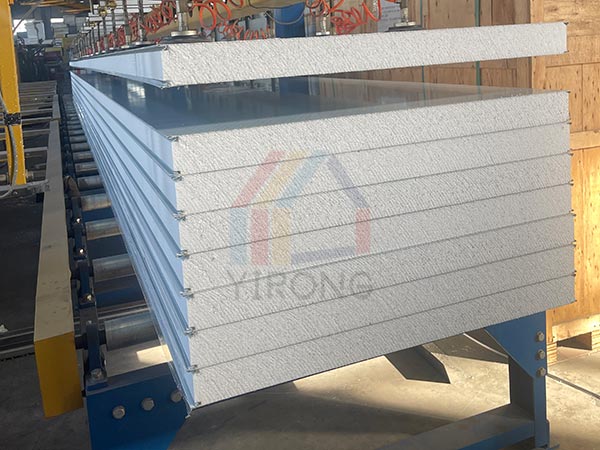

Against the dual backdrop of global energy efficiency standards and frequent extreme weather events, the insulation performance of building envelope structures has become a core link in reducing carbon emissions and achieving energy-saving goals. EPS foam insulation panels have become the preferred insulation material for metal frame buildings (such as industrial plants, cold chain logistics centers, temporary facilities) due to its advantages of light weight, high thermal insulation and low cost. However, metal frames have strong thermal conductivity and significant thermal bridging effects. Improper installation may result in energy loss of up to 30%.

Cold regions (such as Northern Europe and Canada)

Challenge: Low temperature causes EPS brittleness, and the thermal bridge effect exacerbates the risk of condensation.

Installation points: Adopt continuous laying and fixing with thermal anchor bolts to avoid direct contact between the metal frame and the insulation layer. Fill the seams with polyurethane foam adhesive.

Damp and hot regions (such as Southeast Asia and South America)

Challenge: High humidity causes EPS to absorb water and expand, posing a risk of mold growth.

Installation points: Add moisture-proof and vapor barrier film (such as polyethylene film), and use interlocking overlap and silicone sealant for EPS board joints.

Strong wind earthquake zones (such as Japan and the Caribbean Sea)

Challenge: The earthquake caused EPS foam insulation panels displacement and strong winds overturned the roof.

Installation points: Use seismic rubber gaskets between EPS panel and metal frame, and add steel wire mesh reinforcement at the edges.

Pre treatment of metal frame: remove surface oil stains and rust, apply anti rust primer (such as epoxy zinc rich paint).

Flatness calibration: Error ≤ 3mm/m ², fill closed cell foam adhesive in local depressions.

Anchor method:

Mechanical fixation: Self tapping screws (made of stainless steel) penetrate the EPS foam insulation panels and fix it to the frame, with a spacing of ≤ 300mm, and the screw head needs to sink 1-2mm into the board surface.

Adhesive fixation: Use polymer modified adhesive mortar (tensile strength ≥ 1.0MPa), with a full bonding method covering an area of ≥ 60%.

Thermal bridge design: Rubber gaskets (thermal conductivity ≤ 0.035W/(m · K)) are added to the contact surface between the metal frame and EPS.

Horizontal overlap: Adjacent EPS foam insulation panels are laid with staggered seams, with an overlap width of ≥ 100mm, and fixed with locking card slots.

Longitudinal seam: stepped interlocking overlap (50mm offset per layer), with foam polyurethane (density ≥ 35kg/m ³) injected at the seam.

Door and window opening treatment: EPS sandwich panel extends 50mm to the outside of the opening, and is covered with alkali resistant fiberglass mesh cloth to enhance crack resistance.

Pipeline through wall: Glass wool is filled between the embedded sleeve and EPS foam insulation panels, and aluminum foil tape is wrapped around the contact surface between the sleeve and EPS.

Expansion joints: expansion joints shall be set every 30m and filled with polyethylene foam rod+silicone sealant.

| Performance Metric | EPS Foam Insulation Panel | EPS Sandwich Panel | |

| Thermal Conductivity | 0.035–0.041 W/(m·K) | 0.028–0.033 W/(m·K) | |

| Compressive Strength | 100–200 kPa | 300–500 kPa (metal panel-reinforced) | |

| Thermal Bridging |

| 90% reduction via composite design | |

| Installation Efficiency | Labor-intensive | Factory prefabricated, 4-hour on-site lifting |

Climate adaptability:

Arctic scientific research station: The sandwich panel is equipped with a rock wool fireproof layer, which combines -60 ℃ insulation and A-level fire resistance.

Desert photovoltaic power station: The surface aluminum zinc layer reflects 90% ultraviolet rays and reduces the internal equipment temperature by 15 ℃.

Industrial production:

Standardize the size of the board (up to 12m) with an error of ≤± 1mm to reduce on-site cutting losses.

Whole life cycle economy:

Compared to traditional installation, it saves 40% of labor costs and extends its lifespan to over 25 years (with protective coating).

Sustainability:

Recyclable EPS materials account for ≥ 90% and comply with the EU EPD environmental certification.

Nordic Cold Chain Logistics Center: EPS sandwich panel+vacuum insulation panel composite system, achieving precise temperature control of ± 0.5 ℃ in the warehouse.

Middle East data center: Sandwich panel integrated phase change energy storage module, night time cold storage reduces air conditioning energy consumption by 35%.

Breakthrough in fire resistance performance:

Flame retardant EPS (B1 grade) meets the self extinguishing standard by adding phosphorus nitrogen synergistic flame retardants.

Low carbon production technology:

Biomass EPS (straw based material) reduces carbon footprint by 40% and has been applied to zero carbon buildings in Japan.

Intelligent integration:

The sandwich panel is embedded with sensors to monitor real-time parameters such as displacement and humidity of the insulation layer, with a warning accuracy rate of ≥ 95%.

From arctic frozen soil to tropical desert, the innovative application of EPS foam insulation panel is reshaping the global building insulation standard. Its core value lies in balancing cost, performance, and sustainability, providing reliable installation solutions for extreme climate zones.

Choosing EPS sandwich panel is not only about choosing a material, but also about choosing a climate adaptation strategy for the future.