Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

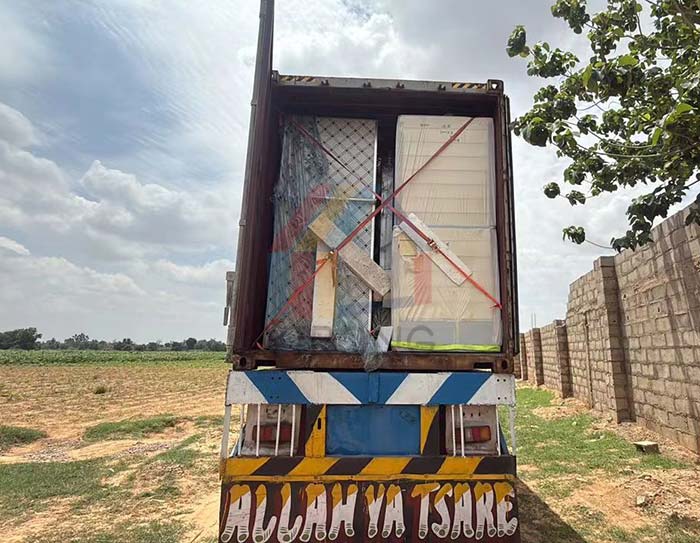

This batch of goods arriving across the Indian Ocean, including 100mm thick PU cold room panels and customized cold storage doors, is about to inject new driving force into Nigeria's fresh cold storage. And their high adaptability is hidden in Yirong's deep understanding of tropical climate and cold storage needs.

The biggest challenge in building a cold storage in tropical regions is not how to freeze it, but how to store it. In high temperature and high humidity environments, ordinary boards are prone to moisture absorption, poor insulation, and rapid loss of cooling capacity. This not only increases power consumption, but also accelerates the deterioration of ingredients due to temperature fluctuations. The emergence of PU (polyurethane) sandwich panels can be regarded as a solution for cold storage.

The PU cold room panels customized by for Nigeria project adopts sandwich structure of double-sided color steel plate and polyurethane foam in the middle. The outer color steel plate has a thickness of 0.5mm and is treated with polyester paint on the surface, which is not only scratch resistant but also corrosion-resistant (with a salt spray test lasting over 500 hours, perfectly adapted to the high humidity environment along the coast of Lagos). More like a layer of protective armor, it isolates external humid and hot air. The polyurethane foam in the middle is the core, and the thermal conductivity is only 0.024W/(m · K) (about 1/20 of the ordinary brick wall). The 100mm thick plate can achieve the thermal insulation effect of 200mm of the traditional brick concrete structure. For example, in a 1000 square meter cold storage, using PU boards can save 30% of electricity costs per year compared to ordinary materials, and the food loss rate can be reduced from 8% to below 2%.

More importantly, the foaming process of PU cold storage board has been optimized by Yirong, with a closed cell rate of up to 98% and no connectivity between cells, which can completely block water vapor infiltration. This is particularly important during the rainy season in Nigeria (with an average annual rainfall of 1800mm). We have conducted simulation tests and found that in an environment with a high temperature of 40 ℃ and a humidity of 90%, only 0.1g of water vapor seeped into the surface of PU board after 48 hours, while 2.3g of water vapor seeped into ordinary color steel plate.

If PU sandwich panel is the insulation wall of a cold storage, then the cold storage door is a sealed lock. Data shows that every minute the cold storage door is opened, it takes 30 minutes for the internal temperature to recover. The loss of cooling capacity caused by frequent opening and closing accounts for more than 20% of the total energy consumption of the cold storage. Therefore, the cold storage door customized by Yirong for the Nigeria project can be regarded as a masterpiece of detail control.

Each door is of double-layer polyurethane filling and metal frame structure. The outer layer is 0.6mm thick stainless steel plate (anti-collision and corrosion resistance), and the inner layer is filled with PU foam of the same density as the wall to ensure that the thermal conductivity of the whole door is consistent with the wall. The door frame is embedded with EPDM rubber sealing strips around it (with an aging resistance life of over 15 years), forming a triple seal when closed. The adhesive strip fits the door panel, the door panel is squeezed against the door frame, and the bottom automatic lifting sealing strip touches the ground. Even in rainstorm days, the external hot and humid air can also be drilled seamlessly.

Considering that Nigeria's cold storage facilities often require the handling of large goods such as whole boxes of fruits and frozen meat, we have specially thickened the door panels (100mm thick) and equipped them with 304 stainless steel floor spring hinges. A single door can bear up to 1 ton and maintain sealing even after 100000 cycles of opening and closing. The Yirong delivery team has made improvements to the packaging based on the local logistics characteristics. The roads in Lagos are bumpy, and trucks are prone to scratching door frames when parked. The corner protectors are made of high toughness ABS material, which has five times the impact resistance of ordinary steel.