Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

In the international building materials trade market, EPS sandwich panels (expandable polystyrene sandwich panels) have always been a rigid material for industrial plants, warehouses, cold storage and other scenes due to their low cost, good thermal insulation and convenient installation. However, buyers often fall into two major dilemmas when purchasing:

Low price trap: Some Chinese factories offer extremely low prices, but the materials are cut corners (such as thin steel plates, recycled EPS), and the process is rough (lax seams, insufficient core material density), resulting in easy deformation after arrival, insulation failure and even safety hazards.

Trust gap: The stereotype of "Made in China" (unstable quality), cross-border communication barriers (language/standard differences), and lack of after-sales guarantee (no one is responsible for transportation losses) make buyers hesitate whether to choose Chinese suppliers.

However, not all factories in China are equivalent to low prices and low quality. Leading enterprises represented by Yirong sandwich panel manufacturer is breaking this dilemma through industrial chain integration, technology upgrades, and service standardization. They can not only provide buyers with wholesale prices that are 10%-15% lower than their peers, but also ensure that the products comply with international certifications such as EU CE and US UL, truly realizing "low cost ≠ low quality".

China is the world's largest EPS sandwich panel production base, with an output accounting for more than 60% of the world's total. Its low-cost advantage is rooted in the complete industrial chain synergy and large-scale production effects. As a leading factory rooted in Henan, Yirong sandwich panel manufacturers have benefited deeply from this model.

The core raw materials of EPS sandwich panels are color-coated steel plates (substrates) and expandable polystyrene (EPS) particles. China's steel industry belt (such as Tangshan, Hebei, and Jiangyin, Jiangsu) gathers branches of large steel companies such as Baosteel and Ansteel, and EPS particle suppliers (such as Wuxi Xingda and Changzhou Huarun) are also highly concentrated. Yirong has established long-term cooperation with these upstream companies and bypasses traders to purchase directly.

Color steel plate: customized thickness (0.3-0.8mm), zinc layer (80-275g/㎡), coating (polyester/fluorocarbon) on demand to avoid the premium of general specifications.

EPS particles: directly purchase raw material particles (rather than finished plates), adjust density (8-20kg/m³) and flame retardant grade (B1/B2 grade) according to product demand, and reduce intermediate processing costs.

Compared with the model of small and medium-sized factories relying on local distributors to purchase raw materials, Yirong's raw material costs can be reduced by 8%-12%.

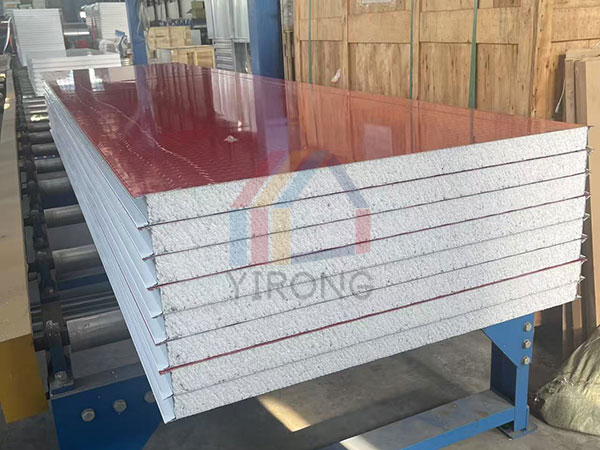

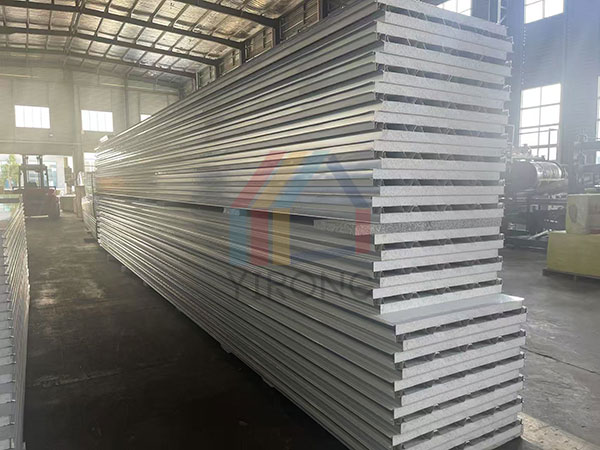

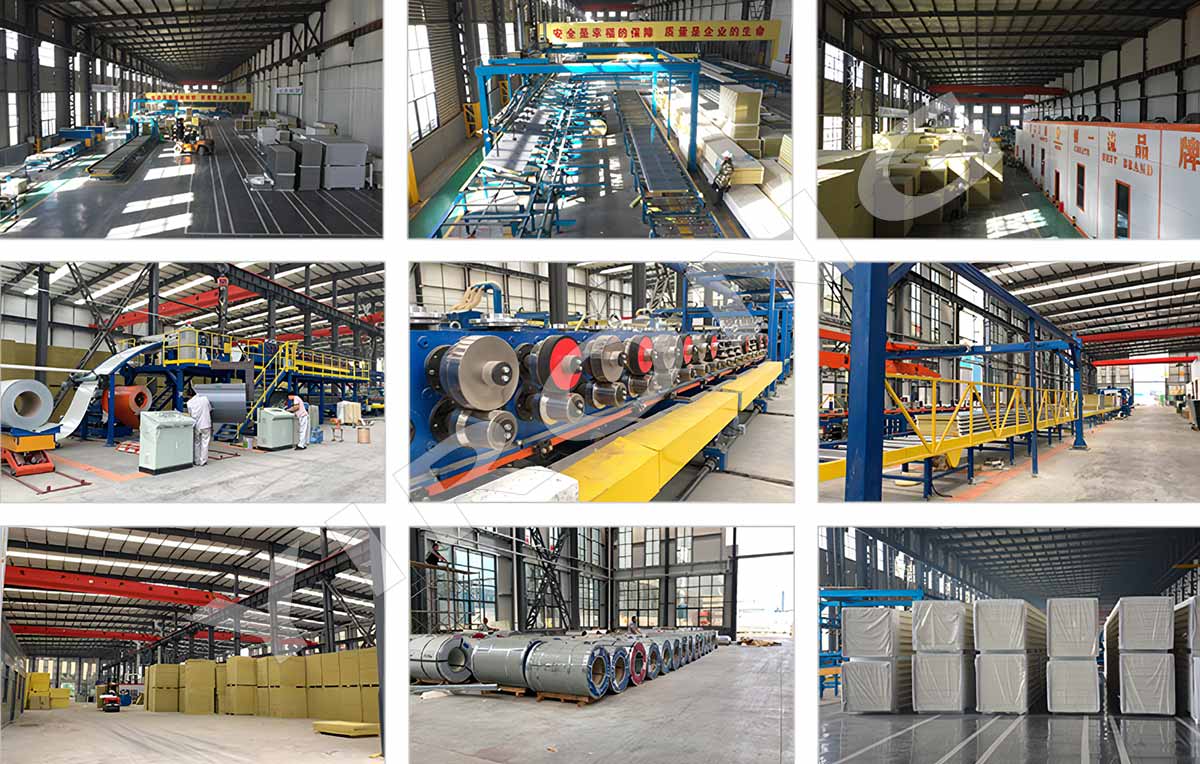

Yirong sandwich panel manufacturer has an annual production capacity of over 5 million square meters and has 10 fully automatic production lines (from substrate cleaning → roll forming → EPS filling → composite curing → cutting and packaging, the entire process is automated).

Reduce manual errors: Traditional factories rely on workers to manually align steel plates and EPS core materials, which can easily lead to loose joints and core material offset (affecting thermal insulation). Yirong's fully automatic composite machine uses laser positioning to control the error within ±0.5mm.

Increase unit time output: The average daily production capacity of a single production line reaches 30,000 square meters (small and medium-sized factories are only 5-10,000 square meters), and fixed costs (equipment depreciation, factory rent) are diluted to 0.1-0.2 yuan per square meter (about 0.3-0.5 yuan for small and medium-sized factories).

Reduce loss rate: The automated production line reduces the scrap rate from 3%-5% of traditional factories to less than 0.8% through intelligent temperature control (EPS foaming temperature ±1℃) and tension control (stable tension during steel plate compounding).

Henan has a dense building materials logistics network:

High-speed rail/high-speed network coverage: It only takes 3-5 hours from the factory to Qingdao Port and Tianjin Port, and the sea transportation cost is 15%-20% lower than that of inland factories.

Mature third-party services: Packaging (waterproof film + wooden pallet), customs declaration (agent customs clearance), insurance (all risks of sea transportation) and other service providers are concentrated. Yirong sandwich panel manufacturers get the agreed price through long-term cooperation, and the logistics cost per square meter is 0.3-0.5 yuan lower than other regions.

Among the same Chinese factories, the cost advantage of Yirong sandwich panel manufacturer is not at the expense of quality. Instead, it has achieved quality premium through technology upgrades and quality control systems. The difference between it and ordinary factories is mainly reflected in the following three aspects:

Ordinary factories often use a combination of thin steel plates and recycled EPS to reduce costs.

Color steel plates: use thin plates below 0.3mm (zinc layer is only 50g/㎡), with poor corrosion resistance (rusting in coastal areas in 1 year).

EPS particles: recycled waste foam (containing impurities, flame retardant failure), resulting in uneven core material density (local <8kg/m³) and substandard combustion performance (B3 grade flammable).

Steel plate selection: according to the buyer's scenario (such as 0.5mm thick + 275g zinc layer + fluorocarbon coating for high humidity in coastal areas, 0.4mm thick + polyester coating for inland warehouses), to ensure a balance between corrosion resistance and cost.

EPS particles: only new materials are used (such as white materials from Wuxi Xingda), and the density is strictly controlled at 12-18kg/m³ (ordinary factories often use low-density materials of 8-10kg/m³, which are easy to absorb water and have poor thermal insulation). Flame retardant grade B1 (self-extinguishing when away from fire) or B2 (flammable but slow burning) grade test reports are provided according to the buyer's needs.

Case: A Middle Eastern buyer needs to build a cold storage (high temperature and high humidity + fire protection requirements). Yirong customized 0.6mm thick fluorocarbon steel plate + B1 grade EPS core material for it. Although the unit price is 8% higher than ordinary plates, the life span is extended from 5 years to 12 years, and the energy consumption of the cold storage is reduced by 20%. The buyer finally repurchased 3 times.

The quality control of ordinary factories relies on pre-factory sampling (sampling rate 5%-10%), which is easy to miss problems (such as hollow core material and insufficient steel plate thickness). Yirong sandwich panel manufacturers have established a three-stage quality control system.

Pre-production test: Each batch of raw materials (steel plates, EPS particles) must pass third-party testing before entering the warehouse (such as SGS steel plate mechanical testing, EPS combustion performance testing).

In-production monitoring: The production line is equipped with online monitoring equipment (such as laser thickness gauges to monitor steel plate thickness in real time, infrared thermometers to monitor EPS foaming temperature), data is synchronized to the ERP system, and abnormalities will automatically alarm and shut down.

Full post-production inspection: Each roll of finished board must pass the appearance and performance double inspection (appearance: no scratches, wrinkles; performance: peel strength ≥ 0.15MPa, thermal conductivity ≤ 0.04W/(m·K)), and unqualified products will be directly scrapped (loss rate ≤ 0.8%).

Certification: Yirong products have passed CE (EU), UL (USA), ISO9001 (quality system) certification, and the test report can be traced back to the production batch, completely eliminating buyers' concerns about unstable quality.

Ordinary factories only provide standardized products (such as 1000mm wide × 1200mm long), and often refuse or increase the price by more than 30% for buyers' special needs (such as 800mm wide, 15 meters long, and surface coating). Yirong sandwich panel solve this difficulty through flexible production.

Flexible production line: The width of the substrate can be adjusted (700-1250mm), the length can be set (3-15 meters), the density/thickness of the core material can be adjusted (to meet different insulation needs), and customized orders account for 40% (only 10% for ordinary factories).

After-sales guarantee: Provide transportation loss compensation (free reissue if the damage rate on arrival is greater than 1%), and return and exchange for quality problems (returnable within 30 days after inspection and confirmation), reducing the trial and error cost of buyers.

For the core difficulties of foreign buyers in cross-border procurement, Yirong sandwich panel manufacturers provide solutions through transparent, standardized, and localized services.

Solution: Provide free samples (5-10㎡), and buyers can entrust third-party organizations (such as SGS, BV) to test. Support video factory inspection (show production lines, raw material warehouses, quality control processes), or arrange field visits.

Solution: Clearly define the production schedule when signing the contract (such as completing production 10 days after the contract is signed and arriving at the port in 15 days), and provide an ERP system to view production progress in real time. Cooperate with international logistics companies (such as Maersk and Mediterranean Shipping) to provide sea/air options (urgent orders can be shipped by air and arrive at the port in 48 hours).

Solution: Prepare certification in advance according to the buyer's target market (such as SABER for export to Saudi Arabia and INMETRO for export to Brazil), and provide certification pre-assessment services (buyers provide product uses, and Yirong recommends the required certification type). For special needs (such as UV resistance requirements), the steel plate coating (adding UV agent) or EPS formula (adding anti-aging agent) can be adjusted.

Solution: Clearly define the quality dispute resolution process in the contract (such as the third-party inspection fee is borne by the responsible party). Insure each batch of goods for all risks of ocean freight and war insurance, covering losses such as fire, collision, and moisture during transportation. Set up an overseas customer service team (English/Spanish/Arabic) to respond to customer complaints within 48 hours.

In the global building materials trade, low cost should not be synonymous with low quality, but should be a comprehensive reflection of China's supply chain efficiency, technological innovation and service capabilities. The practice of Yirong sandwich panel manufacturer has proved that through the integration of the industrial chain to reduce costs, technological upgrades to ensure quality, and localization of services to solve pain points, Chinese suppliers can completely become the best choice for foreign buyers to provide low-cost and high-quality EPS sandwich panels.

For buyers, choosing Yirong is not only a purchase, but also a deep participation in the upgrading and transformation of China's manufacturing industry. From price-driven to value-driven, from trading relationships to long-term partners, this is the new competitiveness of China's supply chain in the global market.