Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

In the field of industry and construction, rock wool sandwich panels have become the standard for scenes such as factories, warehouses, cold chain logistics centers, and public facilities due to their excellent thermal insulation, fireproof and moisture-proof, and lightweight properties. But facing the rockwool insulation sheets with thicknesses ranging from 50mm to 200mm on the market, how to choose the right thickness according to needs?

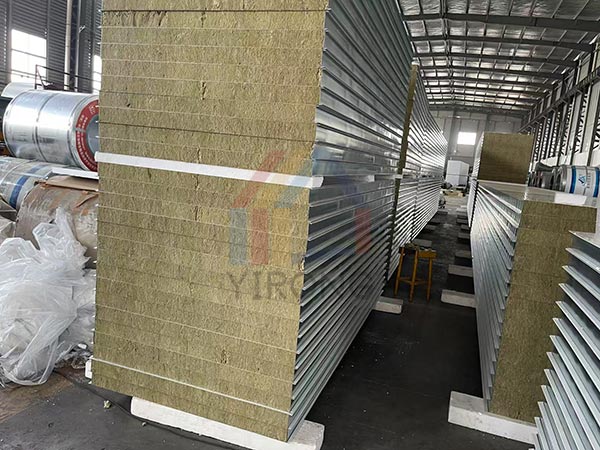

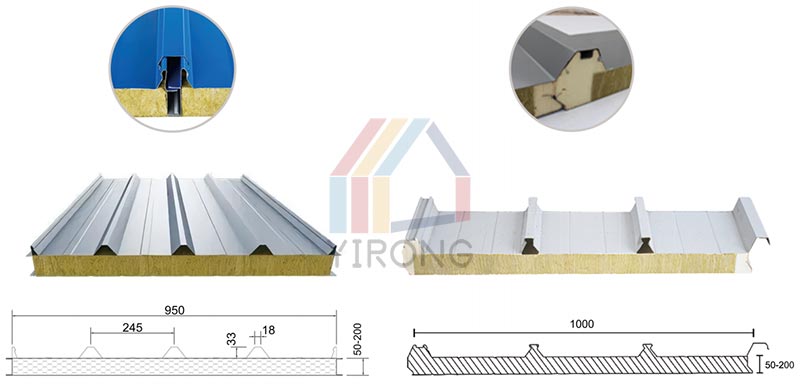

Rock wool insulation board is composed of two layers of metal panels (color steel plate/aluminum-magnesium-manganese plate) and the middle rock wool core material. Its core performance (insulation, fireproof, load-bearing) is directly related to the thickness of the rock wool core material. Simply put:

Increase in thickness: Increase in rock wool filling → Reduced thermal conductivity (improved thermal insulation performance), more stable fire rating (rock wool itself is A1 non-combustible material), and enhanced compression/impact resistance.

Thickness reduction: cost reduction, but may sacrifice insulation effect or fail to meet high fireproof/load-bearing requirements.

Therefore, thickness selection is essentially a balance between demand, cost, and performance, and needs to be comprehensively judged in combination with the functional requirements of specific scenarios.

The application scenarios of rock wool sandwich panels cover three major fields: industry, commerce, and civil use. Different scenarios have significant differences in the priority of insulation, fireproofing, load-bearing, and moisture-proofing. The following is a thickness selection guide for typical scenarios (taking the mainstream market as an example).

Core requirements: insulation (constant temperature in the workshop), fireproofing (equipment heat dissipation/circuit safety), and lightweight (reducing foundation load).

Typical areas: China's Yangtze River Delta manufacturing base, Mexico's auto parts factory, and Poland's mechanical processing park.

Thickness recommendation: 80-100mm.

Reason:

The thermal conductivity of 80mm rock wool insulation sheets are ≈0.040W/(m·K) (at room temperature), which can meet the constant temperature requirements of workshop heating in winter and ventilation in summer (temperature difference is controlled at ±5℃).

When the thickness of rock wool is ≥80mm, the fire protection level can stably reach A1 level (in compliance with EU EN 13501-1 and China GB 8624 standards). Even if the equipment in the workshop catches fire, it can effectively prevent the spread of fire.

Compared with 120mm thickness, the self-weight of 80-100mm sandwich panels is reduced by about 15% (weight per square meter ≤12kg), which is more suitable for steel frame load-bearing of large-span workshops (such as 30m span).

Core requirements: insulation in ultra-low temperature environment (-18℃~-40℃), moisture-proof (avoid condensation water freezing), and anti-freeze-thaw cycle.

Typical areas: California agricultural product cold chain warehouses, Australian seafood processing centers, and tropical Southeast Asian drug cold storages.

Thickness recommendation: 120-150mm.

Reason:

The thermal conductivity of 120mm rock wool insulation board is ≤0.038W/(m·K). Under -20℃ environment, the heat loss per square meter is only 1/3 of that of 50mm thickness, which greatly reduces the energy consumption of refrigeration equipment (saving about 30%).

The density of rock wool core material needs to be ≥120kg/m³, and ordinary industrial boards are mostly 100kg/m³ to avoid rock wool shrinkage at low temperatures and panel debonding.

150mm thickness is suitable for ultra-low temperature cold storage (such as -40℃), and with double-sided stainless steel panels (strong corrosion resistance), it can resist the icing problem caused by the penetration of hot and humid air.

Core requirements: fire protection (crowded areas), sound insulation (conference rooms/gymnasiums), and appearance customization (color/texture).

Typical areas: European schools/hospitals, Middle East convention centers, South American stadiums.

Thickness recommendation: 100-120mm.

Reason:

100mm rockwool insulation sheets can directly meet the A-level fire protection requirements of public buildings (no additional fire retardant coating is required), and complies with international certifications such as British BS 476-32 and American ASTM E84.

The surface of the sandwich panel can be treated with imitation stone grain, metal paint, etc. (such as Yirong's fluorocarbon pre-roller coating process), taking into account both beauty and weather resistance.

If higher sound insulation is required (such as gymnasiums), rock wool and polyurethane composite core materials can be selected, and the volume is ≥35dB when the thickness is 120mm.

Core requirements: low cost, easy to install, and recyclable.

Typical areas: African mining camps, temporary housing for post-disaster reconstruction in South America, and oil field operating areas in the Middle East.

Thickness recommendation: 50-80mm.

Reason:

The cost of 50mm rock wool insulation panel is about 20% lower than that of 80mm, which is suitable for temporary projects with limited budget.

With the quick-install buckle design (such as Yirong's modular connection system), the installation time is shortened by 50%, and 100㎡ can be built in a single day.

The rock wool core material can be recycled and reused, with a recycling rate of ≥80%, which is in line with the global green building trend (such as the EU EPD Environmental Product Declaration).

There are a lot of rock wool sandwich panel manufacturers on the market, and low-priced and low-quality products (such as insufficient rock wool density and shoddy steel plate thickness) may cause insulation failure, fire protection failure and even collapse risks. When choosing a manufacturer, it is necessary to focus on the following 5 indicators.

Density: The density of industrial-grade rock wool needs to be ≥100kg/m³, and the cold chain/public building is recommended to be ≥120kg/m³. Too low density will cause the core material to be loose and the thermal conductivity to increase.

Fireproof grade: Must pass A1 non-combustible certification (such as EU EN 13501-1, China GB 8624), which can be verified by a third-party test report.

Water absorption rate: High-quality rock wool has a water absorption rate of ≤1.0kg/m² (24 hours). For humid areas, hydrophobic rock wool should be selected, and the water absorption rate should be ≤0.5kg/m².

Steel plate thickness: Conventional panel thickness is 0.4mm-0.8mm (0.5mm for industrial plants, 0.6mm for cold chain/public buildings). Too thin and easy to deform (such as bulging under high temperature).

Coating process: Color steel plate needs to use polyester (PE), fluorocarbon (PVDF) or HDP high weather-resistant coating, salt spray resistance ≥1000 hours, suitable for coastal areas.

Aluminum-magnesium-manganese plate: For high-end projects (such as stadiums), alloy grade 3004/3005 should be selected, and the corrosion resistance is better than ordinary aluminum plate.

Composite process: Using continuous roller lamination technology (such as Yirong's fully automatic production line), the bonding strength between the core material and the panel is ≥0.1MPa (national standard ≥0.05MPa) to avoid degumming.

Cutting accuracy: the board length error is ≤2mm, the diagonal error is ≤3mm (the error of ordinary small factories can reach 5-10mm), which affects the installation sealing.

Surface treatment: pre-roller coating process (color difference ≤ΔE1.5) is better than post-spray painting (color difference ≥ΔE3.0), and it is not easy to fade after long-term use.

Required certification: ISO 9001 (quality system), CE (EU), UL (USA), GB (China).

Industry-specific certification: For example, the cold chain industry needs to provide food-grade contact certification (FDA), and public buildings need to provide fire protection Class A test report.

Environmental certification: EPD (Environmental Product Declaration), RoHS (no hazardous substances), in line with European and American green procurement requirements.

Customization capability: Can the thickness (such as non-standard 110mm), color (Pantone color card coverage), and size (maximum width 1.2m, length 12m) be adjusted according to demand?

Global logistics: Is there an overseas warehouse (such as Yirong has warehouses in Southeast Asia and the Middle East) to shorten the delivery cycle (regular 7 days, urgent orders 3 days).

After-sales guarantee: Warranty period, high-quality manufacturers provide 10-year structural warranty and 5-year coating warranty, local technical service team, 48-hour response maintenance.

As the world's leading brand of rock wool sandwich panels, Yirong has been deeply involved in the industry for 17 years and has served more than 5,000 projects in 80+ countries. Its core advantages can be summarized as follows:

Thermal insulation performance: The thermal conductivity of 150mm thick rock wool sandwich panels are ≤0.036W/(m·K) (better than the industry average of 0.038), and the energy saving rate of cold chain projects is increased to 35%.

Fireproof performance: Passed A1 non-combustible certification (EN 13501-1, GB 8624), in a petrochemical project in Dubai, it did not collapse after being burned at 1200℃ for 30 minutes.

Weather resistance: The panel uses PVDF coating (salt spray test ≥2000 hours), and it has no rust for 10 years in the Atacama Desert in Chile (annual rainfall <1mm) project.

Using German TRUMPF laser cutting equipment (accuracy ±0.5mm) and Italian Prima Power roller pressing composite line (bonding strength ≥0.12MPa) to eliminate manual errors.

The sampling rate of each batch of products is 100% (only 5% for conventional factories), and a third-party test report is provided (including 20+ parameters such as thermal conductivity, water absorption, compressive strength, etc.).

Provide integrated design, production and installation services, such as customizing 120mm thick explosion-proof rock wool sandwich panels and anti-static panels for Mexican automobile factories.

The warranty period is 15 years (the industry average is 10 years), covering the three core performances of structural safety, coating anti-corrosion, and core insulation.

The purchase of rockwool insulation sheets are essentially a precise match of demand, performance, and cost. Choose 80-100mm for industrial plants, 120-150mm for cold chains, 100-120mm for public buildings, and 50-80mm for temporary facilities. When choosing a manufacturer, it is necessary to focus on checking the rock wool density, panel thickness, production process, and global service system.

Yirong provides global users with a full-cycle solution from thickness customization to project implementation with high-performance materials, high-precision processes, and customized services. Whether it is to cope with tropical high temperatures, polar cold, or to meet special requirements such as fireproof grade A and food-grade cleanliness, Yirong sandwich panels can help your buildings become safer, more energy-efficient, and more durable with appropriate thickness and reliable quality.

Choose Yirong sandwich panels and let every rockwool insulation sheets become the quality label of the project.